BricsCAD Mechanical

BricsCAD Mechanical

Advanced

Mechanical Design Tools

DWG-based 2D & 3D CAD software for drafting and mechanical design.

BricsCAD makes advanced mechanical design accessible. It is intelligent, flexible, affordable and, above all, enables greater design freedom.

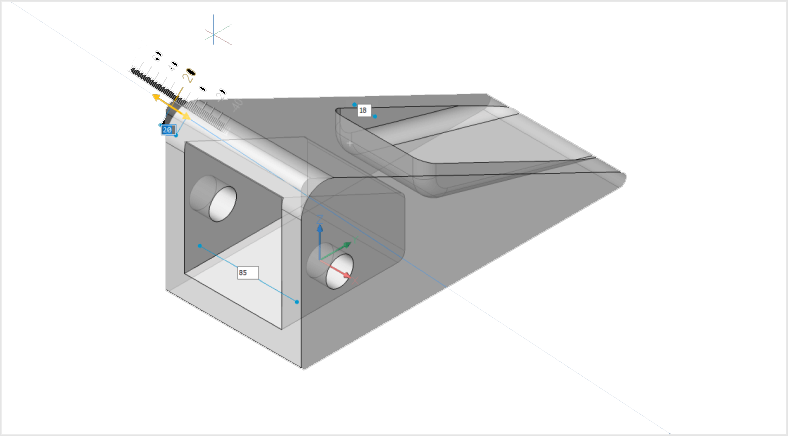

BricsCAD’s unique variational 3D modelling approach gives you the freedom to design how you want to, from concept to detail, with whatever level of parametric control you need.

Quickly develop complex components on their own, or directly within an assembly.

Effortless Design of Parts and Components with BricsCAD Mechanical

With BricsCAD Mechanical, designing parts and components becomes quick and efficient. Start your design process with an easy-to-create 2D sketch. From there, you can extrude, revolve, or sweep your sketch to form a solid 3D part.

Features of BricsCAD Mechanical:

- Start with intuitive 2D sketches.

- Transition seamlessly to 3D solids with extrude, revolve, or sweep tools.

- Built-in 3D primitives for quick initial shape creation.

- Advanced tools like fillets, chamfers, Boolean operations, and direct modeling.

You can also import existing 3D solids and edit them as native components within BricsCAD Mechanical. This ensures a streamlined workflow and better control over your designs.

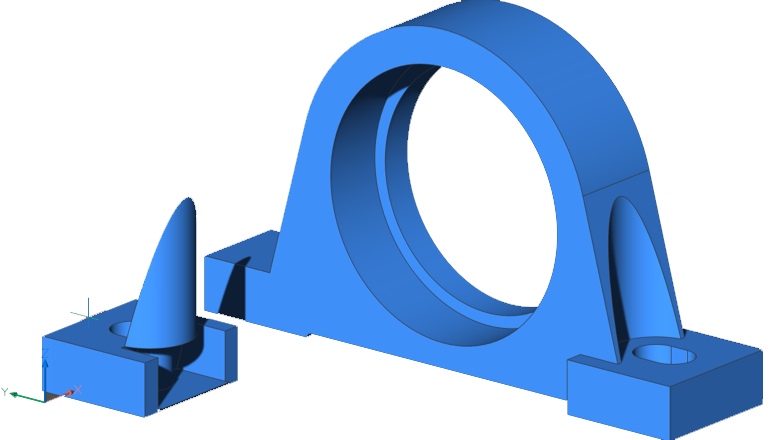

Flexible 3D modeling

Flexible 3D modeling

Our unique 3D design approach combines dynamic and interactive direct modelling with the ability to add parameters only where they’re needed, and without the complexity of a history-based approach.

3D parametrize and constraints

3D parametrize and constraints

The PARAMETRIZE A.I. workflow turns parts into smart, parameter-driven components in seconds. Build constraint systems, drive parts formulatically, build table-driven components and change component parameters in the BricsCAD Properties Panel.

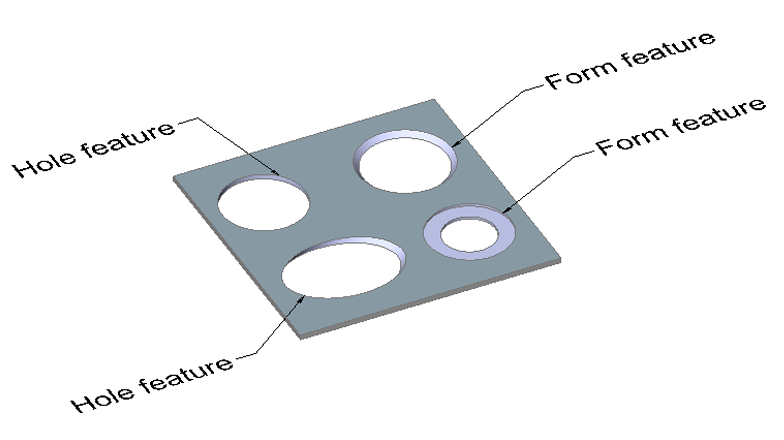

Copy features

Copy features

Model features once and use them many times with powerful tools that copy existing features in 3D solids – such as holes, ribs, pockets.

Hole feature library

Hole feature library

BricsCAD contains a library of standard hole features – you can easily insert holes into your parts via drag and drop actions.

Automatically align copied entities- NEW

Automatically align copied entities- NEW

3D COPYGUIDED automatically aligns copied sets of features to relevant geometry using automatically generated guide curves. You can explicitly select entities to use as guide curves or let BricsCAD determine them based on the drawing elements in your selection.

Create rigid pipework, then add parametric valves, flanges, and associated fastenings. All from a comprehensive library of items, which intelligently resize correctly via a one-click process.

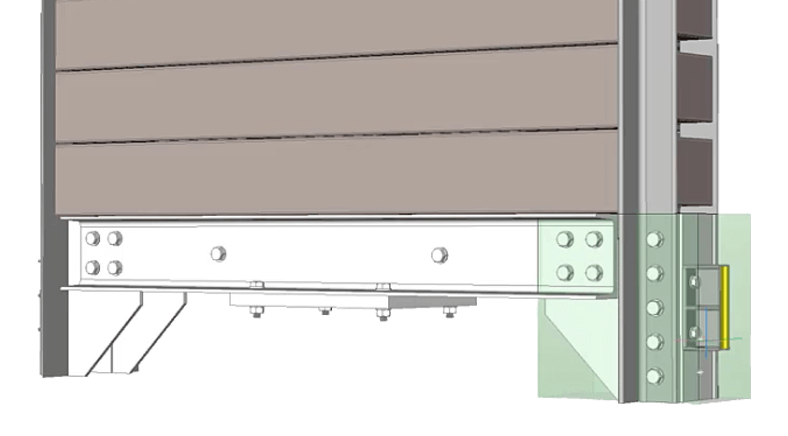

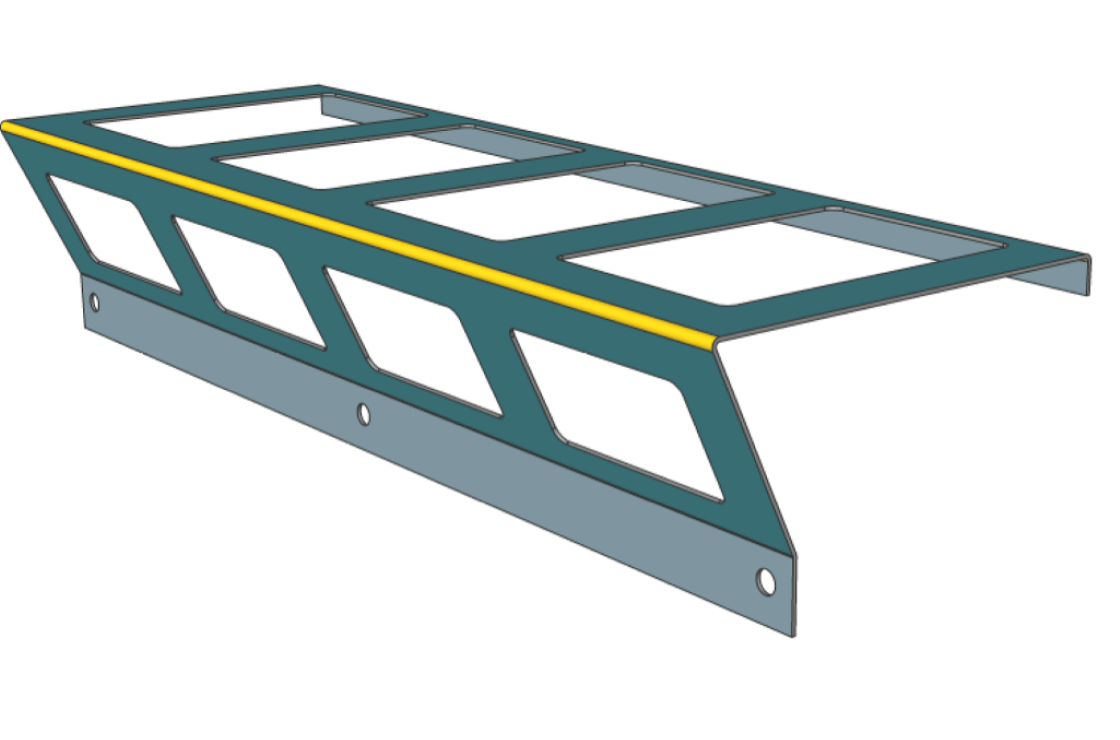

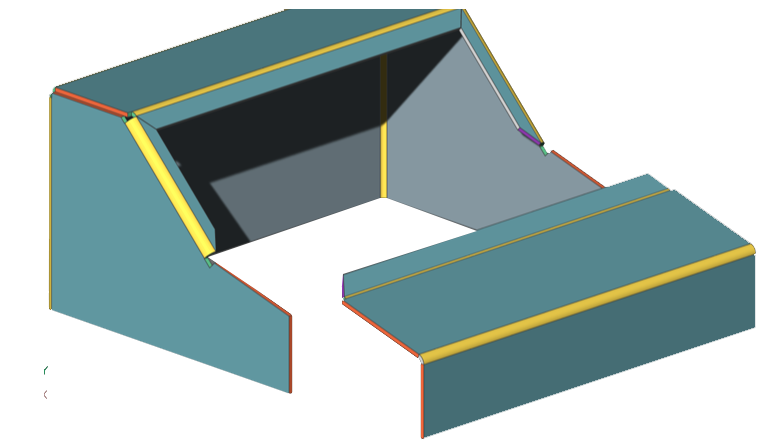

Create sheet metal part designs that are resilient and deeply editable

Not only does BricsCAD Mechanical let you create sheet metal components from scratch, but you can also convert solid parts to sheet metal, automatically, with just one click. This robust approach lets you spend more time evolving your design and less time worrying about redefining sheet metal features.

Sheet metal parts can be edited with the full power and freedom of direct modeling, while the consistency of each feature (flanges, bends, reliefs, junctions) is automatically maintained.

Create un-folded 2D representations that are bi-directionally associated to the 3D sheet metal part. You can also use the unfolding engine to send parts to industry-standard CAM systems.

The flexibility of direct modeling maintains design intent, expressed as sheet metal features – flanges, bends, reliefs, and others.

3D models created in BricsCAD or other CAD systems can be converted to sheet metal automatically, with one click. Features can then be manually refined or changed to quickly achieve your desired form.

Create 2D and 3D unfolded representations to drive CAM systems. The 3D unfolded representation can be edited simultaneously to fix detected conflicts, while keeping the 3D folded part in sync.

Use the full power of 3D constraints, arrays and automatic parametrization to create different design variants from your sheet metal models.

The hem feature for Sheet Metal allows you to model a hemming metal-working processes. BricsCAD supports open hems, teardrops and rounds with user-adjustable parameters.

BricsCAD Mechanical provides a library of parametric form features – such as louvers, bridges, embosses and others. You can also create complex ribs defined by any curve.

You can create lofted sheet metal parts between two arbitrary 3D curves. BricsCAD Mechanical can recognize lofted bends in imported geometry, and automatically decompose them into multiple flanges.

Flanges, Bends, Junctions and Tabs

Flanges, Bends, Junctions and Tabs

Create flanges in multiple ways: using a base flange, an edge flange or a via a contour tool. You can always change the way adjacent flanges connect – via a bend, a junction or a tab-and-slot connection – to improve manufacturability.

Reliefs and Splits

Reliefs and Splits

Avoid material conflicts during the bending process by leveraging the library of reliefs in BricsCAD Mechanical. Split parts in a single click, and automatically propagate the split to other corners in your model.

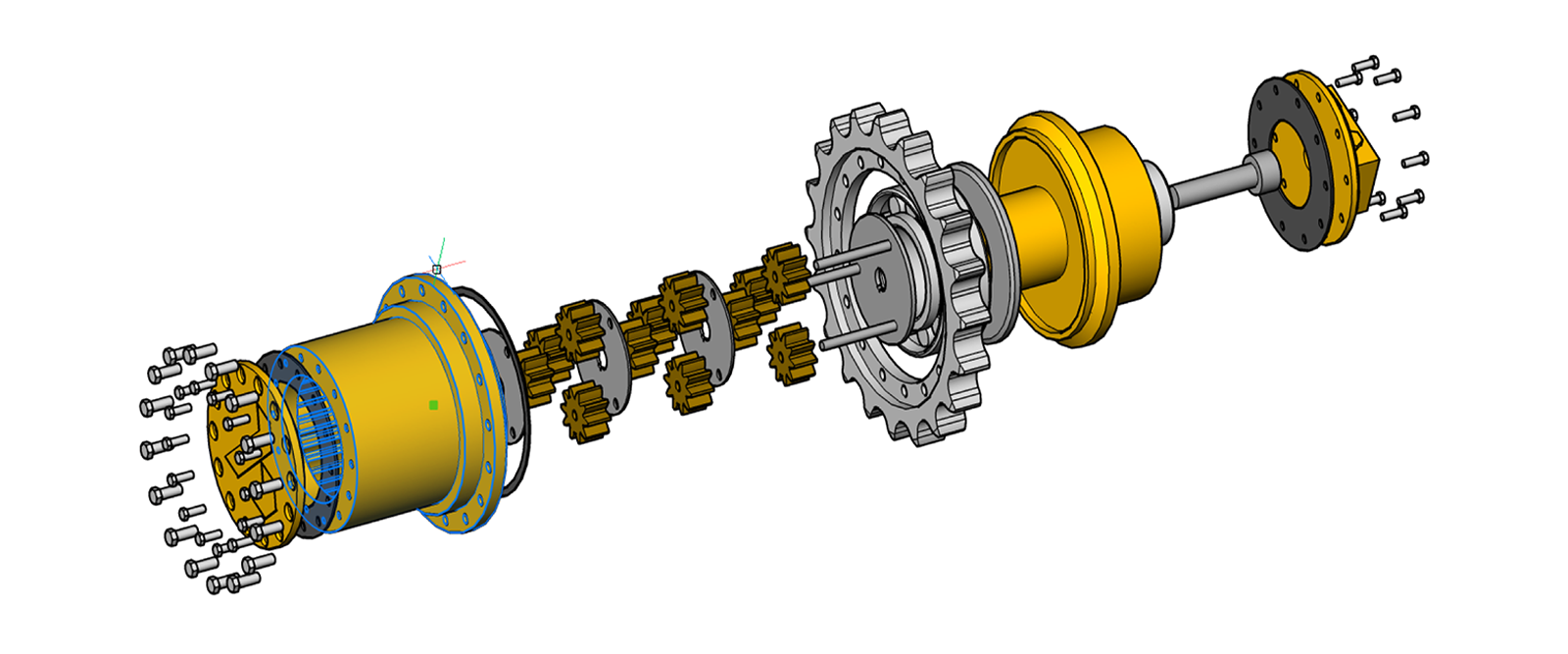

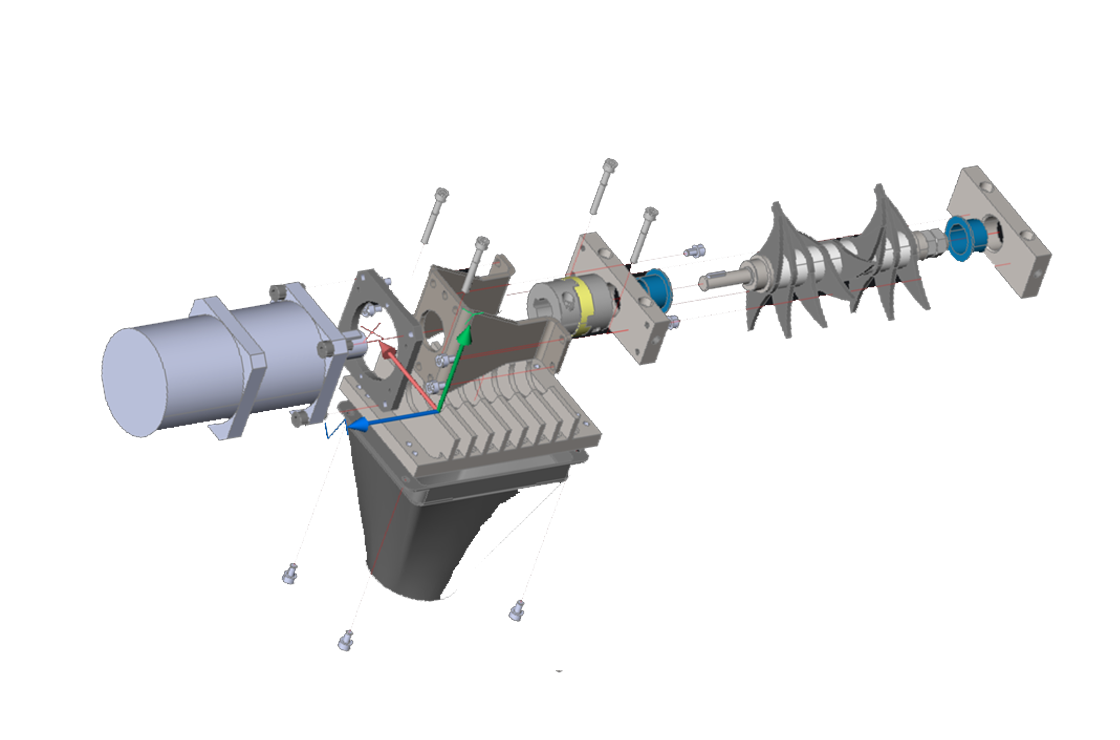

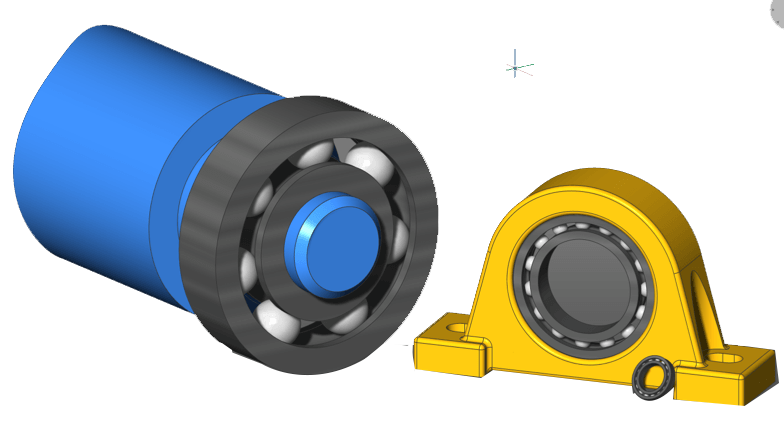

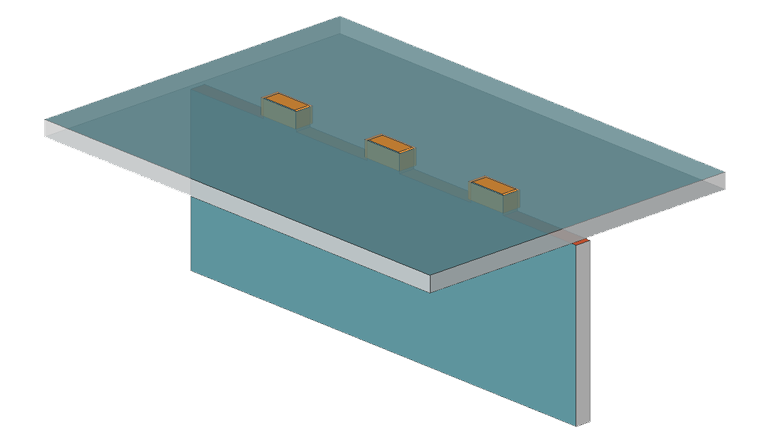

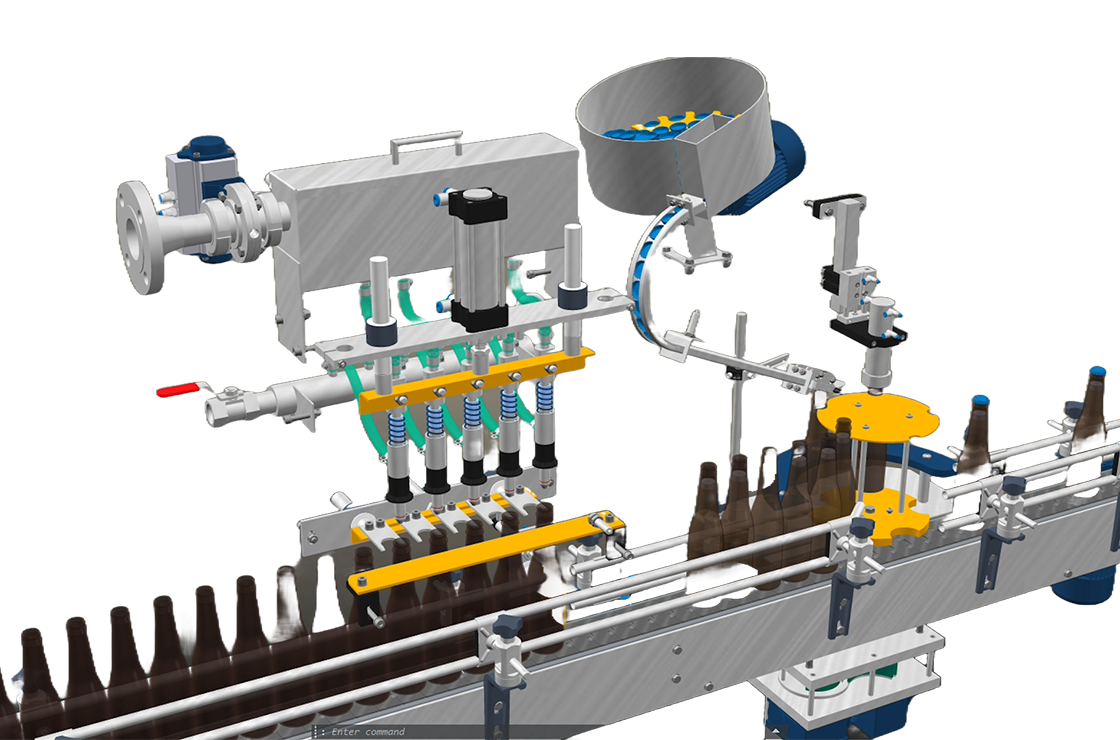

Build potentially complex assemblies and subassemblies using components designed in-house or by others.

BricsCAD Mechanical users can create complex hierarchies of parts and sub-assemblies using bottom-up or top-down design methods. You can import assemblies from different CAD systems using Communicator for BricsCAD, including Parametric geometry defined in those assemblies.

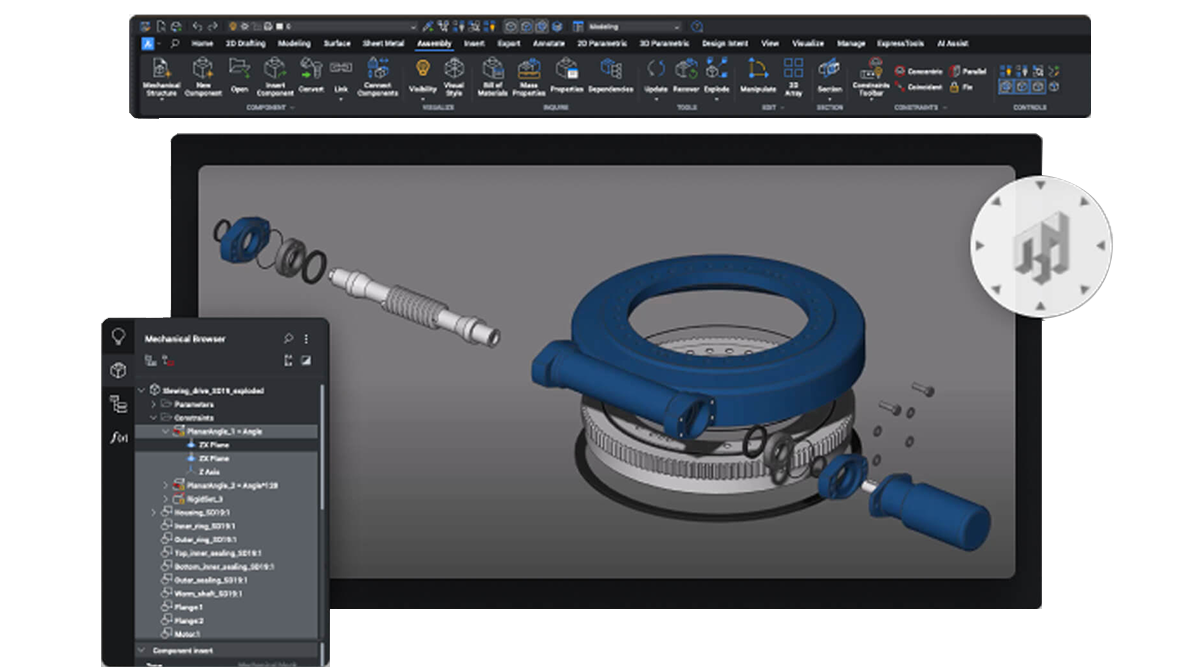

Powerful Assembly Design Tools

Powerful Assembly Design Tools

Quickly build assemblies from existing components, or design new parts within the assembly itself. Apply constraints between parts for a robust representaton of your product design.

Interactively and automatically create a top-level BOM, a parts list, or a hierarchical table from your assemblies. Customize the BOM as you want, define properties for your parts, and link it to your assembly using automatically-created balloon tags.

Use 3D constraints to assemble joints in an assembly. Remaining degrees of freedom can be used to analyze the kinematics of the mechanism. You can create complex 3D animations controlled by these parametric relationships.

Assign materials to parts of your assemblies, and BricsCAD will compute weight, center of gravity, main inertia axes, etc.

BricsCAD Mechanical can create multi-axis exploded views, automatically disassembling complex assemblies and adding trailing lines, in just one click. You can easily annotate and animate the assemblies for technical manuals and documentation.

BricsCAD Mechanical contains a library of 30,000 standard mechanical components of 800+ different types, all with customizable parameters.

BricsCAD offers the best, and most familiar, workflow for turning your mechanical designs into production drawings.

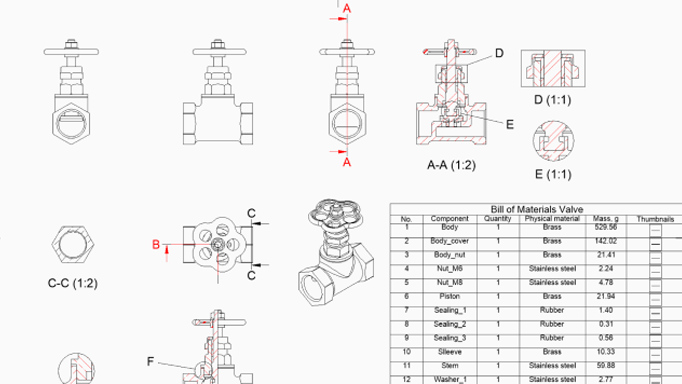

Automatically create drawing views of your 3D parts and assemblies, and detail views easily with dimensions and annotations. If your 3D model changes, generated drawing views are updated automatically.

- Base views

- Projected views

- Section views

- Detail views

- BOM table

- Balloons

Speed up drawing layout using fast, draft-quality views. Then, using multi-core CPUs to create precise views in record time. BricsCAD Mechanical is responsive to your inputs during background drawing generation.

Drawing views remain associated with the 3D model. Change a single part, subassembly, or the whole assembly, and all 2D drawing views are automatically updated, allowing fast design iterations and changes.

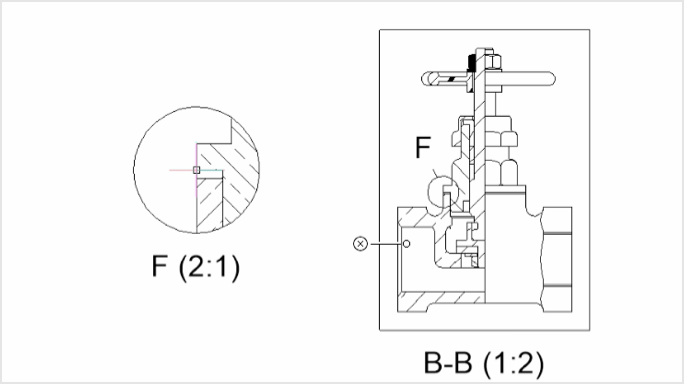

Section views

Section views

You can create section views of 3D parts and assemblies. Section planes can be defined by a line drawn on a base view, or you can create more complex sections: half sections, offset sections and aligned section views.

Detail views

Detail views

BricsCAD Mechanical allows you to automatically create detail views from any existing view in your drawing layout.

The BOM panel lets you manage multiple BOM tables in your drawings. You can format each column individually, set up equations, sort tables, and more.

Balloons

Balloons

BricsCAD Mechanical creates associative balloons for each component in an assembly, and manages the display of those tags in all automatically generated 2D views.

Bring CAD data from many other formats seamlessly into BricsCAD with Communicator for BricsCAD. Easily and quickly build it into your assemblies, modify it via direct modelling, or make it intelligent by applying parameters.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.

Image Courtesy : PTC