Editor’s Note: This post was updated in October 2019.

Digital transformation in the industrial enterprise is happening at breakneck speed.

With the right technology and partners, enterprises are leveraging a breadth of technologies to better prepare their products, processes, and people for the future.

If your enterprise is not already undergoing a digital transformation, the time is now. IDC is predicting global spending on digital transformation to exceed $1 trillion in 2018. And should you think that this trend is just a flash in the pan, think again. Spending on these technologies is predicted to double – yes, close in on $2 trillion! – by 2022.

Leading the investment in digital transformation are discrete and process manufacturers. A recent 451 Research survey found that 68 percent of manufacturers are either evaluating or executing on digital transformation strategies. They’re investing in an array of transformative technologies, like Industrial Internet of Things (IIoT), augmented reality (AR), additive manufacturing, artificial intelligence (AI), automation, blockchain, and more.

However, digital transformation takes on different forms, depending on the industry, and encompasses unique business challenges and goals.

In this post, we’ll review 6 digital transformation examples from industrial enterprises making big changes and seeing incredible results.

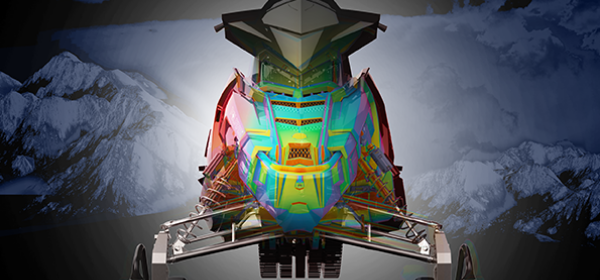

Known globally for its snowmobiles and all-terrain vehicles (ATVs), Polaris looks to deliver a superior end-to-end experience to its customers. With this idea in the forefront, Polaris set out to change the way they designed, manufactured, and serviced their products.

Polaris adopted a step-by-step approach to digital transformation with PTC as a key partner: Starting with product lifecycle management (PLM) and extending the platform through IIoT to augmented reality. Gaining visibility throughout the product lifecycle – from concept to product design to manufacturing to real-world use – was a critical part of the digital transformation journey.

To find out more about the Polaris digital transformation journey, check out our Innovator Spotlight series for in-depth videos and demonstrations.

Takeaway: Frame your digital transformation journey around the core mission and values and don’t think of digital transformation as an end game: Innovation is never complete. whirlpool-digital-transformation

Smart and connected is the wave of the future – and that’s what Whirlpool Corporation is focused on providing customers with each of their products. To support this vision, Whirlpool implemented a PLM solution across the enterprise. With it, they’ve been able to reduce overall system and product complexity, while driving lifecycle processes and efficiencies.

They’ve also been integrating other technologies, such as digital twin, to validate product concepts and features quickly. Low-fidelity prototypes are tested with rapid, cross-functional learning loops, which has reduced time-to-market for new product and increased the speed of innovation.

See the Whirlpool Corporation Innovation Spotlight page for more on how they’re improving customer experience through digital transformation.

Takeaway: Abandoning a siloed approach across the enterprise is a critical piece to driving innovation, promoting efficiency, and improving quality throughout the product lifecycle.

parata-digital-transformation

Parata, a leading provider of pharmacy automation solutions, had what most would call a “good problem” – they were seeing an increase in units installed. It was great news for the business, but it also meant there were more opportunities for service calls.

They knew that – with the right technology – they could deliver improved service for customers and drive increased revenue from the service side of the business. As a forward-thinking business, Parata had previously made the decision to create smart, connected products. However, they lacked a powerful software to fully leverage the data produced or to provide differentiating value to its customers.

With the integration of ThingWorx cloud and other business systems integrations, Parata is more proactive with service and maintenance issues. The solution builds on top of preliminary on-site connectivity and adds real-time analytics, machine learning, and seamless integrations for data-driven insights.

The results have been transformative: reduced costs to service products, improved resource utilization and efficiency, increased service profitability, lower parts consumption, and improved customer satisfaction.

To learn more about Parata’s IIoT initiative and what they’ve learned from the experience, check out this case study.

Takeaway: The traditional approach to product service and repair is weighing businesses down. Take a fresh look at this cost center and how technologies like IIoT and AR can achieve greater efficiency, improved customer experience, and even reveal new opportunities for revenue.

High-quality is a cornerstone of Volvo Group’s products – and a key differentiator in the marketplace. As a leading manufacturer of trucks, buses, construction equipment, and industrial engines, they have launched a digital transformation strategy to increase efficiency, flexibility, and agility in their manufacturing processes.

They’re working on developing a digital thread across multiple business areas: design, manufacturing, and quality control. By having a single source of truth – from both upstream and downstream operations – Volvo Group can quickly respond to changing customer requirements and custom configured products.

Takeaway: With a digital thread as the backbone, there are countless use cases and opportunities to drive digital transformation across the value chain. See the case study for details on how they are delivering data from the digital thread through augmented reality to dramatically improve the quality assurance process.

Lavifood, a Vietnamese company that provides fresh fruit, vegetables, and agricultural products to global markets, is using a suite of technologies to achieve digital transformation. They are integrating IIoT, industrial-grade connectivity, and real-time analytics down to the floor-level. With greater visibility into their plants, they’re able to provide more dynamic responses to issues, reducing downtime and impacts on their perishable goods, which ultimately improves the quality of the product.

Takeaway: Tie your digital transformation strategy to key business goals. For Lavifood, delivering the freshest products to customers is the priority. With this core goal in mind, they’re strategically leveraging technology that enables them to drive operational efficiencies and increase product yields in ways that improve the customer experience.

Howden’s products – industrial air and gas handling equipment – are mission critical for its customers, which made unplanned downtime a significant liability. Wanting to take a more proactive approach with customers to reduce risk and unplanned downtime, they made this area a key focus of their digital transformation initiatives. Their program “Data-Driven Advantage” leverages innovative technologies, like IoT, augmented and mixed reality, and digital twin, to better meet the needs of customers and create new business opportunities.

Takeaway: Howden identified a shortcoming in their long-term customer care and identified a way to solve it through pairing technologies they were already using (like IoT) with new technologies (AR/MR, Microsoft HoloLens). Read the full case study.

Building a future on flexible, agile technology that’s both scalable and accessible is the foundation of digital transformation. Vital to that goal is partnering with the right technology companies that don’t just enable change but accelerate it.

These few examples are just a glimpse into the transformative possibilities and innovation happening in the industry now. You can find more examples of digital transformation in our State of Industrial Digital Transformation report.

A recent Industry Week article posited that “digital transformation” isn’t the most appropriate name for what’s currently happening in manufacturing and other industries.

Here’s senior technology writer John Hitch: “With how the benefits of the cloud, artificial intelligence, Industry 4.0, and blockchain are already impacting plants and factories on every level, the more correct term may be digital metamorphosis.”

He expands, “The concerted effort to become more digital signifies that [companies] choose to become more like a quick and nimble butterfly. It's an oftentimes laborious, resource-intensive process, but one that results in new abilities, like being able to rise above the dense foliage and pick out the best customers and suppliers.”

So, the question is: Will you be a caterpillar or a butterfly?

As we look ahead to 2019 and beyond, digital transformation – no matter what you call it – is an imperative for the manufacturing enterprise.

Nancy White is a content marketing strategist for the Corporate Brand team at PTC. A journalist turned content marketer, she has a diverse writing background—from Fortune 500 companies to community newspapers—that spans more than a decade.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.