Get ready to fly high with Creo 10. PTC’s Creo 10 and Creo + are here! It will become possible to work at a faster pace, with the new improved functionalities of Creo 10, and thus it will make your every day more productive.

Creo 10 gives its customers and users the power to manage, visualize, and design smarter utilizing Additive and Subtractive Manufacturing, Generative Topology Optimization, visualized flexibility, Generative Design, Electrification, Simulation, Model-based Definition (MBD), IoT, and Augmented Reality (AR). On the other hand, Creo +, is available as a SaaS and it provides cloud-based tools for real-time collaboration and streamlined license management and deployment.

In Creo 10, there is an improvement in multibody design workflows which has added a new split/trim feature. The Stretch tool in Warp has also been modified in Creo 10. There is an enhancement in the model tree in Creo 10 so that the confusion between restructuring and reordering an assembly can be removed.

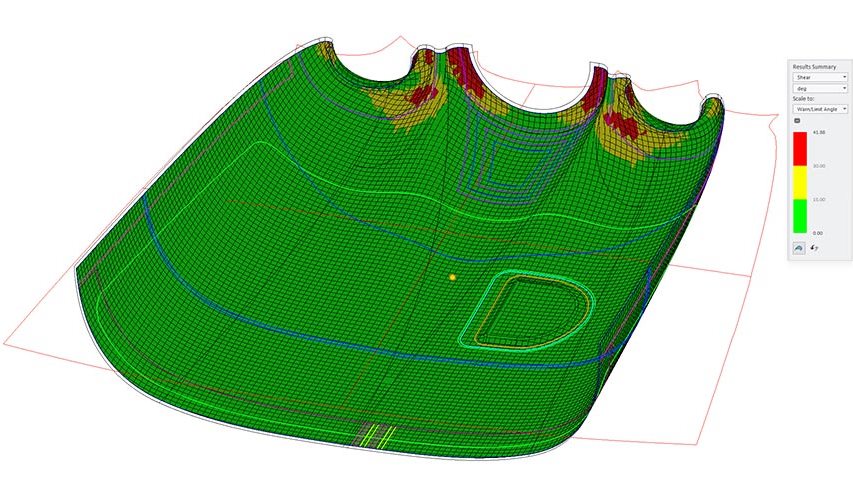

Creo 10 introduces a new dedicated composite design. Creo 10 provides a wide range of functionalities to define individual ply sections and for creating Inner Mold Line (IML) quilts and resulting solid geometry.

The improved design in Creo 10 offers rich capabilities to apply splicing or darting operations to relieve stresses in the fabric. This design automatically creates final layup sequence’s complete and detailed plybook documentation.

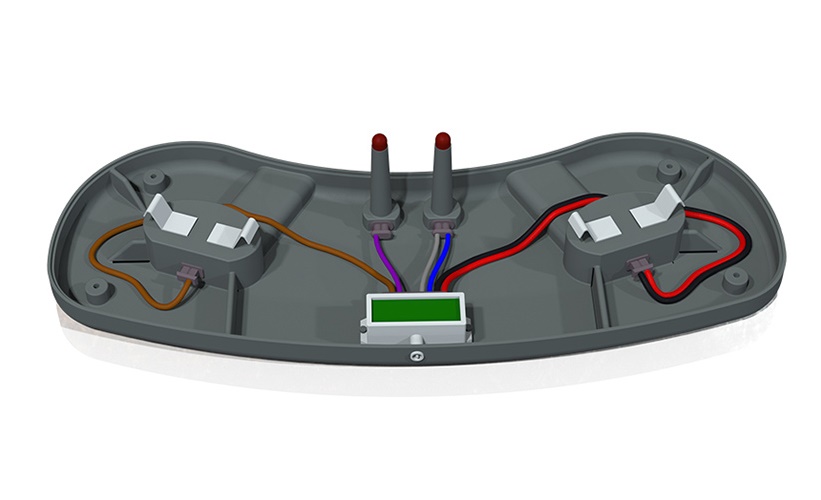

Electrification is becoming a key initiative for many industries due to which Creo 10 has improved design tools for cables and harness design to help you create and manage wiring harnesses. The Split or Merge Harness Tool permits the reuse and collaboration of sub-harness assemblies. Creo 10 has enhanced and extended ECAD capabilities, which include the better handling of ECAD hole parameters and the import of paste masks too. This produces better control of PCB design.

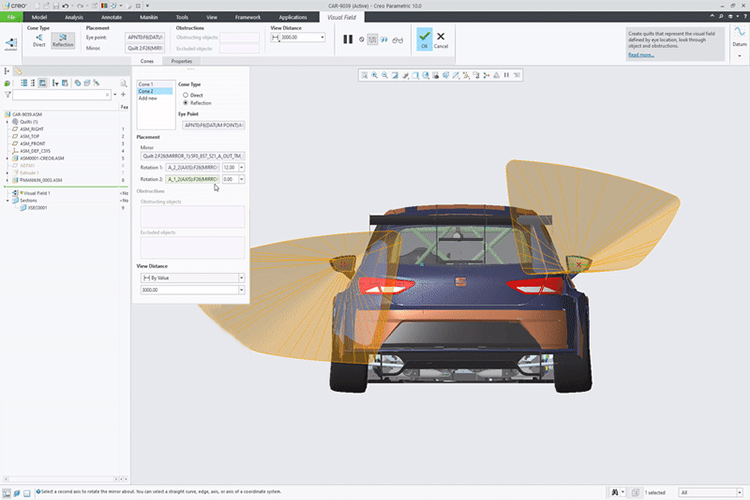

PTC’s Creo 10 has improved its Visual Field features and Manikins. It has identified such enhancements that enable you to account for the range of movement and the uniqueness of users. Creo 10’s Visual Field features are improved and hence can now perform a reflection analysis by selecting an object. In Creo 10, Manikins are developed such that they support multiple-reach envelopes.

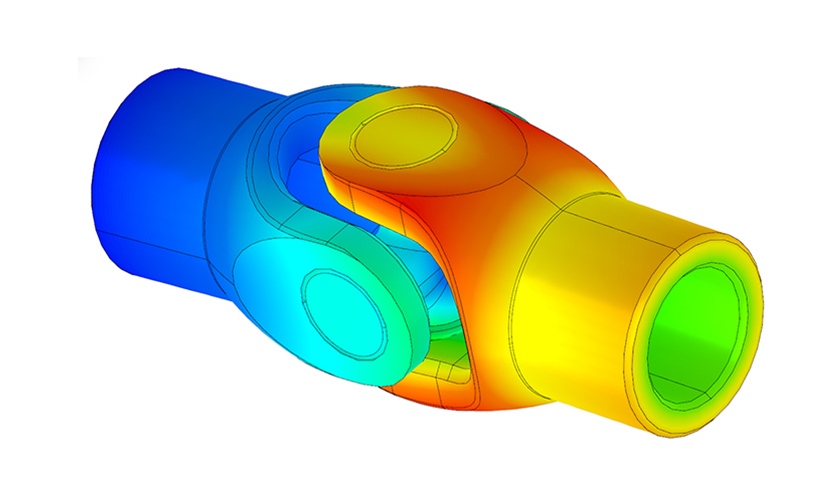

PTC Creo 10 has introduced a new feature known as Creo Ansys Simulation Advanced. This feature is the latest addition to the Creo simulation offerings, which provides you options you might have never considered and imagined. It provides support for multiple tasks including support for combined thermal and structural analysis, support for non-linear materials, and support for non-linear contact including new contact types such as frictional and rough, etc.

Creo Simulation Live has made available expanded contact simulation options and improved result options for structures and fluids. Creo Flow Analysis has been improved in Creo 10 with better animation and Creo Simulate has been improved and enhanced with multibody support.

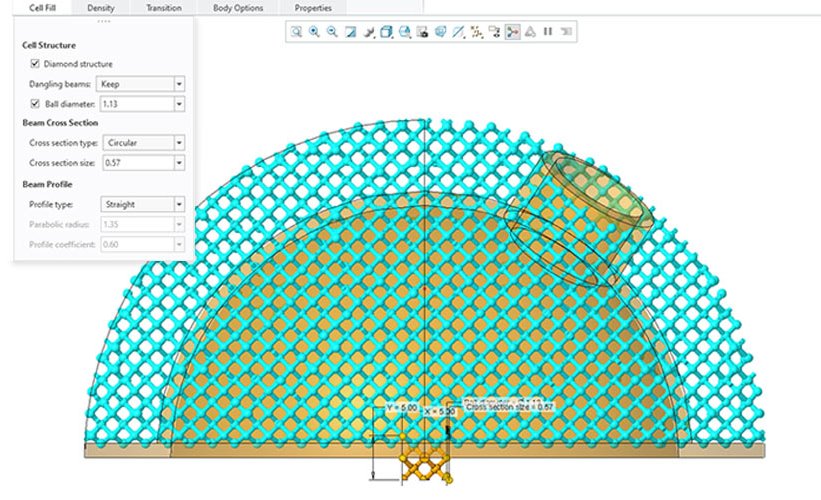

Creo 10 has improved and advanced its additive and subtractive manufacturing features thus it is possible to deliver high-quality manufacturable products.

Additive Manufacturing:- PTC Creo 10’s latest functionalities allow users to create several new beam-based lattice types such as dodecahedron, rhombic, rhombic with diamond structure, and elongated dodecahedron. Simulation-based variable wall thickness and highly efficient l-graph-wrapped (IWP) lattice cells are creo 10’s some of the new advanced features.

Subtractive Manufacturing:- PTC Creo 10’s now supports barrel tools for both wall and floor 5-axis finish. This reduces the toolpath time and increases the finish quality of the surface. Creo 10 has also introduced additional control for CUTCOM and clearance to Area turning.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.