In today's competitive manufacturing landscape, streamlining your product development process is crucial for success. A key component for achieving this is effective Bill of Materials (BOM) management.

In the realm of modern manufacturing and product development, efficient Bill of Materials (BOM) management plays a pivotal role in ensuring smooth operations, reducing costs, and enhancing overall productivity. As industries evolve and products become more complex, the need for robust Bill of Materials management software becomes increasingly critical. Modelcam Technologies emerges as a leader in this domain, offering comprehensive solutions that streamline Bill of Materials management and empower businesses to excel in their respective fields.

A Bill of Materials (BOM) is a detailed list of all the components, materials, and subassemblies required to create a finished product. It serves as the backbone of your product development process, providing vital information for:

Engineering: Defining product structure and functionalities.

Production Management: Assessing expenditures, organizing manufacturing procedures, and overseeing inventory levels.

Purchasing: Identifying and sourcing required materials.

Service: Identifying replacement parts and troubleshooting issues.

A Bill of Materials (BOM) serves as the foundation of any manufacturing process. It is a list of assemblies, components, and raw materials required to build a product. Effective Bill of Materials management involves not only creating and maintaining accurate lists but also ensuring synchronization across various departments including design, engineering, procurement, and production.

BOM software simplifies the complexities associated with managing product structures and enables seamless collaboration among teams. It facilitates:

Reliability: Providing all stakeholders with the latest BOM revisions for consistent operations.

Efficiency: Streamlining workflows from design through production, reducing errors and delays.

Visibility: Providing transparency across the supply chain, enabling better decision-making.

We, at Modelcam Technologies, offer state-of-the-art BOM management software designed to address these challenges effectively. We design our solutions with industry-specific needs in mind, serving sectors like automotive, aerospace, consumer electronics, and beyond.

Traditional methods of Bill of Materials management, such as spreadsheets and siloed databases, often lead to:

Error-prone: Manual data entry increases the likelihood of inaccuracies.

Incompatibility: Different departments may use separate systems, hindering collaboration.

Version Control Issues: Difficulty maintaining consistency across revisions.

Restricted Visibility: Absence of up-to-date insights into BOM data.

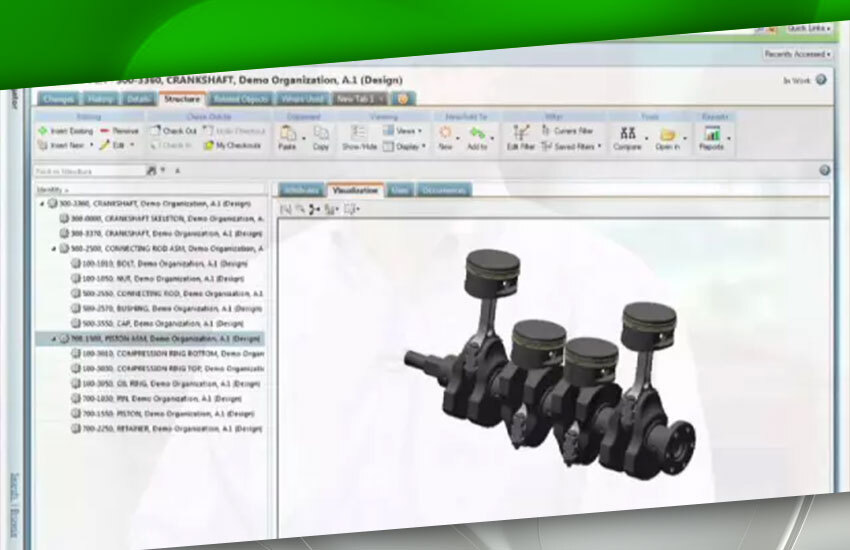

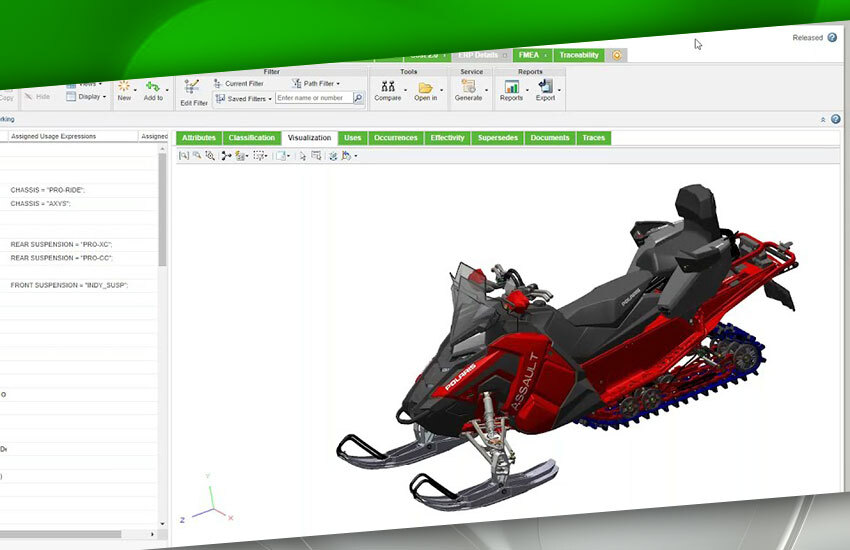

PTC's Windchill PLM solution serves as a centralized hub for streamlined BOM management. It streamlines the process by providing:

Single Source of Truth: Windchill serves as a central repository for all BOM data, ensuring accuracy and consistency across departments.

Configurable BOM Views: Create customized BOM views with specific information relevant to different teams (e.g. engineering BOM vs. manufacturing BOM).

Revision Control: Track changes in BOMs, ensuring everyone has access to the latest version.

Change Management: Manage changes to BOMs with approval workflows and impact assessments.

Integration with CAD Systems: Windchill integrates with popular CAD software, allowing you to automatically generate BOMs directly from design models. Modelcam Technologies, with its expertise in PLM consulting services, can help with seamless integration between Windchill and your specific CAD systems. Read our blog, Windchill PLM Integration for more information about how Windchill integrates with other CAD software or ERP systems.

Improved Collaboration: Windchill provides a platform for engineers, manufacturers, and other stakeholders to work together on BOMs, fostering better communication and faster decision-making.

Enhanced Visibility: Gain real-time insights into BOM data, including cost estimates, inventory levels, and lead times.

To leverage the complete benefits of Windchill PLM software, manufacturing, marketing and sales teams must get trained on how to use it so that they can utilize it fully. Find out more about this by exploring our blog, Why Invest in Windchill PLM Training for Your Team?.

Implementing Windchill Bill of Materials management can lead to several significant benefits for your organization, including:

Reduced Costs: Improved accuracy reduces errors in purchasing and production, leading to cost savings.

Increased Efficiency: Streamlined workflows and collaboration save valuable time and resources.

Improved Product Quality: Consistent and accurate BOMs ensure consistent product quality.

Faster Time to Market: Efficient BOM management facilitates faster development cycles.

Enhanced Innovation: Improved collaboration and visibility empower teams to explore new ideas and products.

Modelcam Technologies, a leading provider of PLM consulting services, can help you implement Windchill BOM management and unlock its full potential.

Assess your current BOM management needs

Develop a customized Windchill implementation strategy

Integrate Windchill with your existing systems

Train your staff on using Windchill effectively

By partnering with Modelcam Technologies, you can leverage our expertise to optimize your BOM management and achieve your product development goals.

Expertise: With years of experience in PLM consulting services, Modelcam Technologies understands the unique challenges faced by different industries and provides tailored solutions.

Innovation: Constantly evolving our software to incorporate the latest technological advancements, ensuring that our clients remain at the forefront of industry standards.

Support: Dedicated customer support and training programs to assist clients in maximizing the value of our BOM management software investment.

Efficient management of the Bill of Materials (BOM) is crucial for optimizing product development costs and efficiency. PTC Windchill offers a powerful solution for streamlining BOM management, providing a centralized platform with features like revision control, configurable views, and integration with CAD systems. By implementing Windchill BOM management and partnering with PLM consulting companies like Modelcam Technologies, you can experience a range of benefits and gain a competitive edge in the market.

Ready to skyrocket your BOM management? Contact Modelcam Technologies today to discuss your PLM requirements and learn how Windchill can help!

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.