Adopting cutting-edge technologies that increase accuracy, productivity, and efficiency is essential to remain ahead of the competition in today's ever changing manufacturing environment. CAD customization is one such technology that has the potential to drastically change industrial procedures. Manufacturers can improve overall productivity, minimize errors, and streamline their design processes by customizing CAD (Computer-Aided Design) software to suit their needs. This blog discusses the importance of CAD customization for all manufacturing companies as well as the ways in which custom CAD solutions may improve product development, design, and manufacturing.

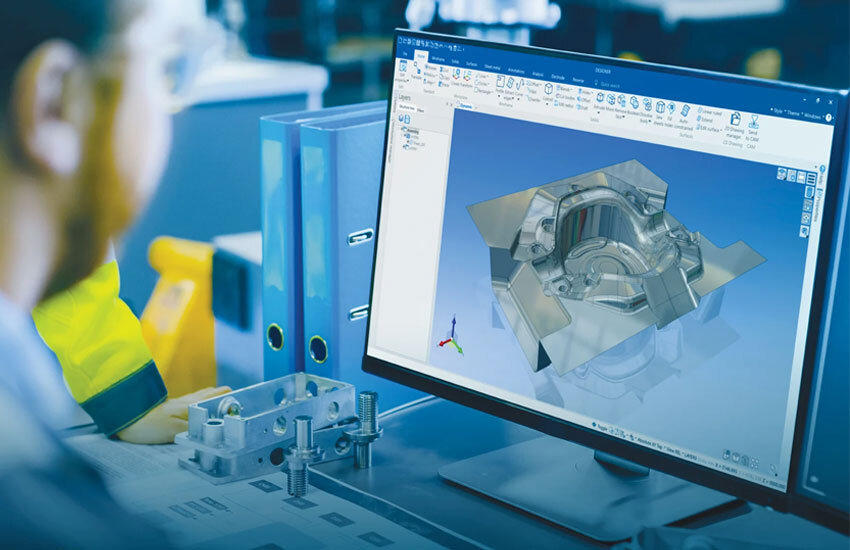

CAD customization is the practice of altering standard CAD software to meet the particular requirements of a company, procedure, or sector. From changing user interfaces to developing unique features that complement certain workflows, this customization can take many forms. Businesses may increase accuracy, speed up production schedules, and automate repetitive processes with CAD automation for manufacturing. A crucial tool for producers, tailored CAD software guarantees that every step of the design process is optimized for optimal efficiency.

Explore our blog, “Why CAD Customization is Needed?” to understand the need for CAD customization!

Below are some of the important benefits of CAD customization:

The potential of CAD customisation in manufacturing to greatly increase productivity is one of the main benefits of CAD customization in manufacturing. Engineers and designers can operate more effectively when CAD software is customized for particular industrial processes. Repetitive processes are streamlined and manual input is decreased with custom tools and features. Faster design cycles and, eventually, faster product time-to-market result from this.

Customizing CAD for industrial applications minimizes human mistakes. Custom solutions may incorporate built-in tests that detect potential mistakes early in the design phase. Automated error checks on material specifications, dimensions, and tolerances, for example, can help to avoid costly mistakes. Reducing errors is critical in manufacturing, where precision is essential for producing high-quality goods and eliminating waste.

CAD customisation for CNC & 3D printing is very useful in sectors that rely on these technologies. Manufacturers can optimize their designs for CNC machining and 3D printing by updating CAD software to meet the special requirements of these procedures. Custom CAD solutions ensure that the design transfers effortlessly into production, increasing quality and efficiency.

Manufacturers can use industry-specific CAD solutions to streamline their design processes and meet the unique needs of their business. Whether it's automotive, aerospace, electronics, or consumer goods, custom CAD solutions can be built to answer industry-specific difficulties, increasing design speed and accuracy.

Modelcam Technologies recognizes the value of engineering design automation in today's competitive manufacturing environment. Our CAD customization services are specifically designed to help you improve your manufacturing processes. Whether you need CAD software customization services for a specific sector or want to incorporate predictive analytics into your design processes, we have solutions that will match your exact requirements.

Our team of professionals collaborates with businesses to understand their needs and provide custom CAD solutions that increase productivity and lower production costs. With our expertise in engineering CAD customization, we assist organizations in automating workflows, reducing manual effort, and improving overall design accuracy.

Read our blog post, “Why Your Engineering Team Needs CAD Customization Services Today” to find out more about CAD customization services!

In manufacturing, CAD for product design and development is critical in deciding the quality and functioning of the finished product. Businesses that use tailored CAD software can improve their design capabilities and ensure that their goods satisfy unique client requirements. Whether it's CAD automation for manufacturing or incorporating sophisticated design elements like parametric modeling, CAD customization guarantees that product designs are perfectly matched with project objectives.

Customized CAD tools, for example, can assist designers in simulating product performance under real-world settings, resulting in more informed design decisions. This predictive power reduces the likelihood of design faults, resulting in higher-quality products and increased customer satisfaction.

Modelcam Technologies specializes in engineering CAD customization to help you streamline the product development process. By adding automation into CAD workflows, we enable firms to eliminate human participation in repetitive operations, hence shortening production timeframes. Our CAD customization services also improve team cooperation by providing a consistent platform for design, production, and quality control. This cohesive strategy helps to avoid inconsistencies and ensures that everyone associated with the project is on the same page.

Manufacturing productivity is directly related to design efficiency. Optimizing manufacturing with CAD customization allows firms to avoid design bottlenecks, reduce the need for costly rework, and accelerate production timeframes. Customizing CAD software helps to align design tools with the specific needs of each manufacturing organization, resulting in increased throughput and cost effectiveness.

CAD automation for manufacturing enables manufacturers to automate operations such as part creation, material selection, and even final inspection, ensuring that all processes are simplified and optimized for performance. This automation, backed by AI-driven solutions, allows firms to prioritize innovation and high-value activities over monotonous manual operations.

When manufacturers can deliver high-quality items on schedule and within budget, customer happiness automatically rises. CAD software customization ensures that designs adhere to client specifications, decreasing the likelihood of costly changes or redesigns. This leads to faster deliveries and, consequently, improved levels of customer satisfaction.

Modelcam Technologies provides CAD customization services, allowing firms to adjust swiftly to client needs and market developments. Manufacturers can remain ahead of the curve, improve product quality, and meet customer expectations by employing AI-powered predictive analytics and tailored tools.

The significance of CAD customization in the industrial business cannot be underestimated. The benefits of CAD customisation in manufacturing are apparent, ranging from mistake reduction and increased productivity to workflow optimization and product quality improvement. Businesses that invest in tailored CAD software can maintain their competitiveness, decrease expenses, and increase operational efficiency.

Manufacturers may maximize the potential of their design and manufacturing processes by utilizing Modelcam Technologies CAD solutions. Our custom CAD solutions are tailored to the unique needs of each industry, guaranteeing that firms achieve peak performance and growth. Whether you need CAD customization for CNC and 3D printing or optimize manufacturing with CAD customization, Modelcam Technologies is your reliable partner for success.

Embrace the future of manufacturing with custom CAD solutions - your way to innovation, efficiency, and success.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.