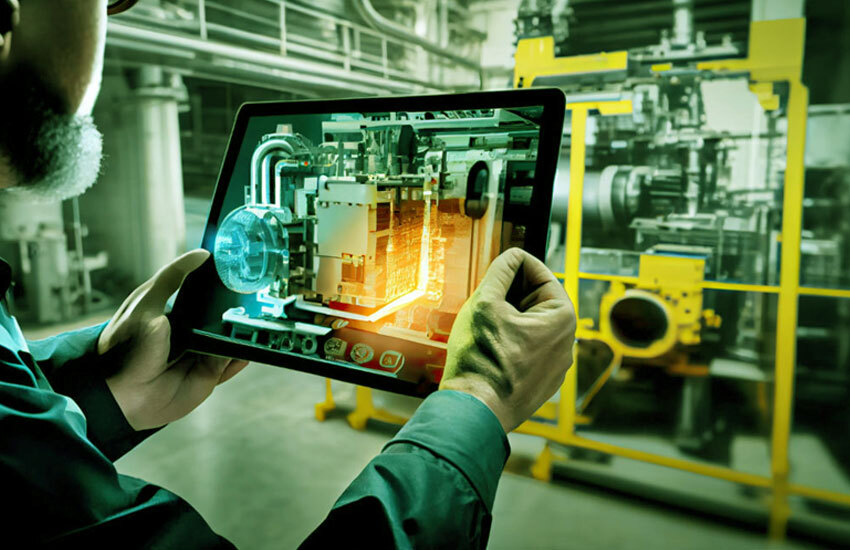

Companies in today's quickly changing manufacturing and engineering sectors are constantly looking for ways to improve operations, cut costs, and speed product development. This has resulted in an increased use of PLM (Product Lifecycle Management) Services for Manufacturing. PLM is an integrated approach to product design, production, and lifecycle management. It provides a strong foundation for managing the entire product lifecycle, from concept to end-of-life, resulting in increased efficiency, innovation, and cost-effectiveness.

To gain more insight into the benefits that PLM services offer to medium-scale businesses, read our comprehensive blog, “The Benefits of PLM Services for Small and Medium Enterprises (SMEs)”!

In this article, we will look at the top benefits of PLM services for manufacturing and engineering and how organizations may use PLM solutions for product development and manufacturing process automation.

One of the most major benefits of PLM software is its ability to optimize manufacturing processes. Manufacturing firms frequently face issues such as data silos, miscommunication, and manual processes, which can cause delays and errors. PLM systems centralize all product-related data, making it readily available to all stakeholders. This increases collaboration across departments, including as design, engineering, production, and procurement.

PLM services by Modelcam Technologies provide enterprises with greater visibility, real-time tracking, and automated workflows, providing a seamless and efficient production process. Whether managing designs, inventory, or production schedules, PLM systems assist decrease operational complexity and enable easier transitions from one phase to the next.

PLM for product development is critical for organizations who want to bring innovative goods to market swiftly and efficiently. PLM software enables teams to work together on designs, simulate product performance, and track changes throughout the development process. By improving collaboration and reducing errors, PLM optimizes product development timelines.

Furthermore, PLM deployment services by Modelcam enable firms to harness strong capabilities such as 3D CAD integration, virtual simulations, and testing, hence speeding up the product development process. This is significant in industries such as automotive and aerospace, where product complexity and time-to-market are important.

Time-to-market is a critical aspect influencing a company's competitive advantage in the marketplace. The capacity to bring items to market quickly enables organizations to capitalize on trends and better fulfill client wants. PLM services for manufacturing help firms optimize processes, automate jobs, and improve team collaboration.

PLM systems alleviate bottlenecks that create delays by offering real-time updates and integrated design, production, and testing capabilities. Manufacturers may significantly reduce development periods and deliver products more quickly by using cloud-based PLM for engineering firms or PLM solutions for automotive and aerospace.

Effective collaboration is essential for the success of product development and manufacturing. Businesses can use Engineering PLM solutions to guarantee smooth communication among cross-functional teams such as R&D, design, manufacturing, and quality control. PLM systems create a single source of truth, providing real-time data and updates to all team members, ensuring everyone is on the same page.

PLM implementation in engineering makes it easier to manage complex projects by offering tools for measuring progress, managing modifications, and sharing feedback in real time. This increases productivity, lowers errors, and speeds up decision-making processes. For example, PLM services by Modelcam Technologies allow teams to share product design files, BOM (Bill of Materials), and supplier information in a single repository, ensuring efficient project management and communication.

Maintaining product quality and industry standards is critical in manufacturing, particularly in regulated industries such as automotive and aerospace. PLM solutions provide tools for automated quality assurance, document management, and compliance monitoring.

PLM optimizes product quality control by centralizing data and integrating quality management systems, guaranteeing that products satisfy the necessary standards and regulations. Whether it's assuring compliance with industry certifications or tracking material requirements, PLM systems offer a complete approach to managing quality and compliance across the product lifecycle.

One of the most compelling reasons to engage in PLM services for manufacturing is the possible cost savings. PLM systems increase operational efficiencies by automating mundane operations, boosting communication, and providing greater visibility into the manufacturing process.

In addition, cloud-based PLM for engineering firms reduces the requirement for costly on-premise infrastructure. This not only reduces capital expenditures, but also increases scalability and flexibility. Furthermore, PLM solutions enable firms to better manage resources, optimize production schedules, and decrease waste, all of which result in significant cost savings over time.

Many manufacturers are increasingly focusing on sustainability, and PLM for product development can help support their efforts. PLM systems help manufacturers develop more environmentally friendly and sustainable goods by managing data on materials, energy consumption, and product end-of-life management.

PLM services by Modelcam Technologies enable enterprises to track the environmental effect of their products throughout their lifecycle and assure compliance with sustainability standards. PLM solutions help to shift to a circular economy by optimizing material use and boosting recycling and reuse.

PLM systems provide firms with important insights by gathering and analyzing data from across the product lifecycle. Data automation and predictive analytics skills allow manufacturers to make more educated decisions based on real-time data rather than intuition or historical data alone.

For example, AI-driven solutions integrated into PLM systems can estimate demand trends, predict maintenance requirements, and manage inventory levels. Businesses may use these data-driven insights to make better decisions that improve overall performance, lower costs, and increase customer happiness.

As manufacturing firms grow and enter new markets, they need scalable systems that can handle greater complexity. PLM deployment services by Modelcam provide flexible and customizable solutions that can scale with the business. Whether scaling production volumes, managing more complex product portfolios, or entering new regions, PLM services ensure that businesses can continue to innovate and meet changing market demands.

The benefits of PLM software to manufacturing and engineering companies are great. From boosting cooperation and accelerating product development to improving quality and lowering costs, PLM solutions for manufacturing are critical for remaining competitive in today's fast-paced corporate climate. Companies that use PLM services by Modelcam Technologies can streamline their product lifecycle management procedures, boost efficiency, and open up new growth prospects.

If you are looking to optimize your manufacturing process automation or need expert support with PLM implementation in engineering, Modelcam Technologies provides some of the best PLM solutions in India and the USA. Their experience with PLM consulting and PLM implementation services ensures that businesses can successfully develop, manage, and optimize the potential of PLM systems.

Businesses that integrate the correct PLM services can achieve increased efficiency, shorter time-to-market, and a more sustainable approach to product lifecycle management, resulting in a stronger bottom line and more delighted consumers.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.