AI in manufacturing is transforming industrial processes, increasing productivity, and lowering operating costs in the current era of digital transformation. Automation, predictive analytics, and intelligent decision-making are made possible by artificial intelligence in manufacturing, which makes factories more intelligent and productive. Businesses leading the way in creating AI-powered manufacturing solutions that boost output and simplify processes include Modelcam Technologies.

To know more about how AI in manufacturing is building the future of smarter factories, explore our blog, “AI in Manufacturing: Shaping the Future of Smarter Factories”!

Let's examine how artificial intelligence is changing the manufacturing sector and the top ten uses of the technology.

Predictive maintenance is among the most significant uses of AI in industry. AI systems examine real-time data from industrial machinery to identify possible failures before they happen by utilizing machine learning in manufacturing. AI-powered solutions increase equipment lifespan, save repair costs, and decrease downtime.

Early fault detection through predictive analytics.

Lowers maintenance expenses and unscheduled downtime.

Ensures continuous manufacturing, which improves total customer satisfaction ratings.

In manufacturing, maintaining product quality is essential. AI for manufacturing quality control employs data analysis and computer vision to identify flaws instantly. Manufacturers can maintain high standards while reducing waste and errors thanks to AI-powered factory automation.

Detects flaws automatically and accurately.

Reduces waste and increases ROI from AI investments.

Increases conversion rates with reliable product delivery.

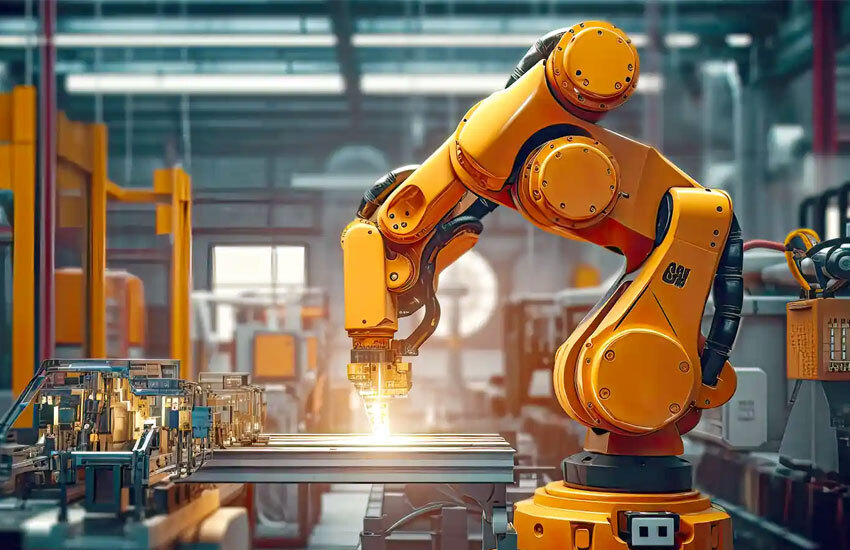

Production lines are being automated by AI and robotics in industry. To improve productivity, accuracy, and safety, human workers are accompanied by collaborative robots (cobots) that are outfitted with AI-driven algorithms.

Makes AI-driven process automation possible for higher productivity.

Lowers operating expenses and human error.

Effectively satisfies high production demands, improving customer engagement.

AI for supply chain optimization improves inventory control, demand forecasts, and logistics. Manufacturers can anticipate market trends and optimize supply chain operations using AI-powered sales forecasting.

Minimizes delays and maximizes supply chain efficiency.

Makes use of data-driven decision making to increase accuracy.

Improves inventory planning, which raises engagement rate improvement.

AI-driven solutions can automate repetitive operations found in manufacturing processes. AI-powered robotic process automation (RPA) increases productivity, decreases manual involvement, and guarantees operational accuracy.

Lowers operating expenses by using AI-enabled manufacturing solutions in India.

Increases efficiency while improving performance metrics.

Allows human workers to focus on more sophisticated tasks by automating repetitive processes.

AI in production planning can help manufacturers optimize production workflows, scheduling, and resource allocation. An AI based digital strategy Implementation guarantees that operations go smoothly and waste as few resources as possible.

Enhances demand forecasts through market trend analysis.

Uses intelligent scheduling to increase productivity.

Ensures effective sales optimization by minimizing bottlenecks.

By evaluating data from sensors, cameras, and Internet of Things devices, (artificial intelligence) AI for industrial safety and risk management guarantees worker safety. In order to prevent mishaps, AI-powered systems identify dangerous situations and send out real-time alerts.

Enables real-time monitoring to improve worker safety.

Predictive analytics is used to avoid hazards.

Lowers liability and insurance premiums.

In order to develop intelligent production environments, the idea of AI in smart factories combines cloud-based AI solutions, IoT, and AI-powered factory automation. Implementing these technologies to increase manufacturing efficiency is Modelcam Technologies' area of expertise.

Uses AI (artificial intelligence) in industrial engineering to improve production processes.

Employs business intelligence to make smarter choices.

Improves customer retention through effective production processes.

Augmented reality (AR) and artificial intelligence (AI) together provide immersive training, maintenance, and design visualization solutions. AR apps powered by AI enable employees to engage with virtual production models, increasing productivity and accuracy.

Enhances employee training procedures.

Improves manufacturing's digital transformation tactics.

Uses real-time AR guidance to reduce design and assembly errors.

Manufacturers may improve their sales processes by utilizing AI-powered sales forecasting and customer relationship management (CRM) AI tools. Improved lead generation, conversion rate optimization, and tailored customer engagements are made possible by AI-driven insights.

Increases the level of hyper-personalization in interactions with customers.

Employs AI marketing automation to run focused ads.

Increases the customer experience enhancement through insights powered by AI.

AI in manufacturing is growing quickly, enhancing industrial processes with intelligence, automation, and efficiency. There is no denying AI's influence in the manufacturing sector, from AI-driven process automation to AI for quality control in manufacturing. AI-enabled manufacturing solutions in India, such as Modelcam Technologies, assist companies in improving their performance indicators and achieving higher operational success.

Industries can increase production efficiency, guarantee quality, and improve consumer experiences by adopting smart manufacturing with AI. AI will drive manufacturing in the future, and companies that embrace these developments will continue to be inventive and competitive in the global marketplace.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.