For engineers and designers, attaining design flexibility and efficiency is crucial in the cutthroat world of product development. One of the best options is PTC's Creo software, which provides an extensive toolkit to improve the design process from ideation to manufacturing. This article highlights the main characteristics and advantages of Creo software while examining how it increases design freedom and productivity.

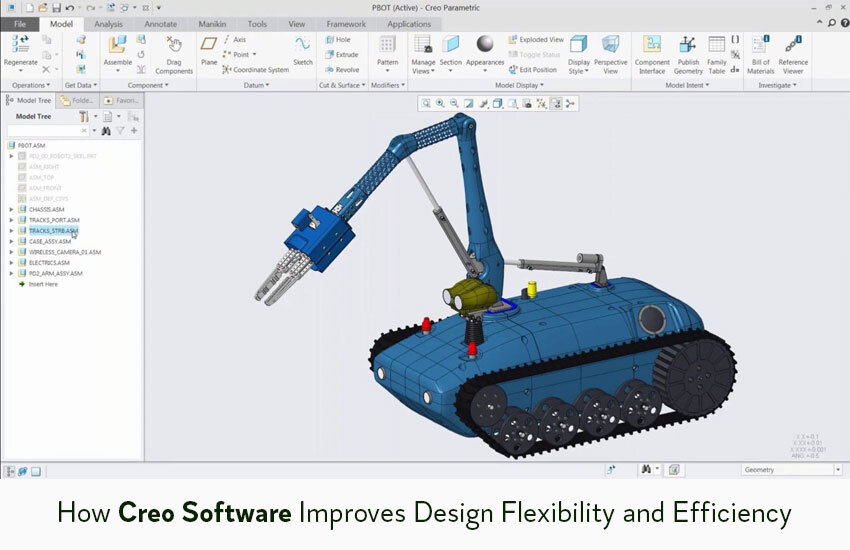

PTC Creo, is a powerful 3D CAD program that supports product design and development in a variety of sectors. With the help of its assortment of tools, engineers may easily and precisely build complex geometries through parametric and direct modeling. Creo increases productivity and streamlines workflows by combining sophisticated design capabilities, simulation, and production processes.

To get more information about Creo software, check out our blog post on, “Why Leading Companies Prefer Creo Software for Product Development?”!

Creo's dual modeling method is one of its most notable characteristics. By defining features and dimensions with consistent relationships, parametric modeling enables designers to ensure that the design intent is maintained across changes. Conversely, direct modeling offers the freedom to work with geometry without being constrained by preset parameters. This combination enables engineers to select the best method according to the needs of the project, allowing for both quick prototyping and intricate design modifications.

Because Creo incorporates sophisticated simulation features, engineers can carry out dynamic simulations, computational fluid dynamics (CFD), and finite element analysis (FEA) inside the design environment. These tools speed up the development cycle and eliminate the need for physical prototypes by enabling the early diagnosis of any problems. Design professionals may enhance products' performance, durability, and safety by modeling real-world scenarios.

Designers can customize toolbars, ribbon menus, and shortcut keys to fit their unique processes with Creo's extremely configurable user interface. Engineers can cut down on pointless clicks and expedite their design process by grouping tools according to how often they are used. Additionally, by using folders and custom templates, Creo facilitates workflow automation, guaranteeing consistency between projects and cutting down on tedious activities.

A key component of effective product development is collaboration. By enabling many users to work on the same model at once, Creo makes concurrent engineering easier. This cooperative setting guarantees uniformity throughout the project and speeds up the development process.

Creo's augmented reality integration improves teamwork and design visualization. Engineers can design augmented reality (AR) experiences that let users interact with 3D models in a real-world setting. This immersive visualization helps speed up decision-making processes, improve communication of design intent, and support design reviews.

How Creo compares to rivals like SolidWorks is a crucial factor to take into account when assessing CAD solutions. Creo is perfect for intricate designs and big projects since it has strong parametric and direct modeling capabilities. It offers a complete environment for product development with its sophisticated simulation tools and generative design features. Creo's broad feature set and adaptability frequently make it the go-to option for companies needing complex and highly engineered products, even if Solidworks is renowned for its user-friendly interface and interoperability.

For engineers, using Creo in the design process has several advantages:

Enhanced Productivity: By drastically cutting down on design time and effort, features like automation and generative design free up engineers to concentrate on innovation.

Improved Collaboration: Creo's collaboration capabilities allow several engineers to collaborate on various sub-assemblies at the same time, guaranteeing consistency and speeding up development schedules.

Better Design Quality: By enabling the early identification of possible problems, sophisticated modeling and analysis technologies provide more durable and dependable products.

Flexibility in Design Approach: By combining parametric and direct modeling, engineers can select the approach that best suits each project, taking into account different levels of design complexity.

Creo incorporates AI-powered solutions to enhance decision-making and design productivity. Engineers can automate tedious activities, optimize materials, and foresee design faults with predictive analytics. Simulations driven by AI improve accuracy, cut down on iterations, and speed up time to market. Creo's machine learning algorithms also examine previous designs and suggest enhancements, guaranteeing ongoing innovation.

Creo is extensively used in smart manufacturing and mechanical engineering settings. Digital prototyping, real-time performance analysis, and automated quality control are made possible by its smooth interface with Industry 4.0 technology. Creo is a favored option for businesses that prioritize sustainability and efficiency since engineers may use its predictive maintenance capabilities to optimize machinery designs and lower operating costs.

Creo offers scalable, reasonably priced choices for companies of all sizes, in contrast to many other CAD software packages. Businesses can begin with simple design tools and expand their capabilities as needed. Cloud-based collaboration and subscription-based pricing structures allow businesses to access cutting-edge design tools at a reasonable cost.

In the field of product design, Creo software is a powerful tool that provides unmatched efficiency and flexibility. Its extensive feature set, which includes advanced simulation, generative design, parametric and direct modeling, and more, enables engineers to produce creative, superior products while expediting processes and shortening time to market. Organizations can gain increased productivity, better teamwork, and a competitive advantage in the dynamic field of product development by incorporating Creo into their design processes.

Leading supplier of cutting-edge CAD/CAM/CAE systems, Modelcam Technologies focuses on sophisticated production and product design technology. To improve engineering workflows, the organization provides a variety of services, such as consultation, training, and Creo software deployment. Through advanced simulation, parametric modeling, and digital prototyping technologies, Modelcam Technologies assists businesses in streamlining their design processes, guaranteeing more productivity and creativity in product development.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.