The capacity to effectively develop, test, and prototype products is essential for success in today's cutthroat industry. The development of products has been revolutionized by the use of 3D modeling software, which has become an essential tool for engineers and designers. Whether it is used for digital prototyping, industrial design, or mechanical design, 3D CAD modeling is essential for cutting down on errors and expediting the product development process.

This blog will discuss how 3D modeling may greatly increase accuracy, decrease errors, and ultimately result in superior goods, particularly when used with sophisticated CAD software for product design. We will also explore how the industry is being revolutionized by technologies like BricsCAD for 3D modeling, which make it simple for designers to produce precise, high-quality product designs.

The potential of 3D modeling for industrial design to decrease human error is one of the main factors contributing to its growing popularity. Engineers and designers frequently use blueprints, 2D drawings, or paper sketches to illustrate their concepts in traditional design approaches. This strategy may result in time- and money-wasting production errors, poor communication, and inaccurate computations.

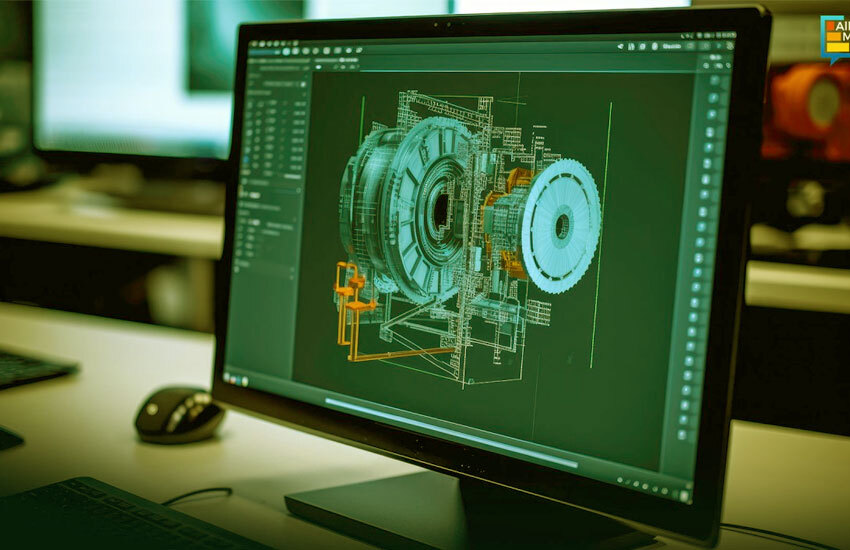

The product design process enters a more accurate digital world with 3D CAD modeling. In order to envisage the finished product and see any design defects early on, engineers can produce incredibly precise, three-dimensional representations of their ideas. This 3D design for manufacturing guarantees that the finished product satisfies all required requirements and tolerances while lowering the possibility of expensive errors.

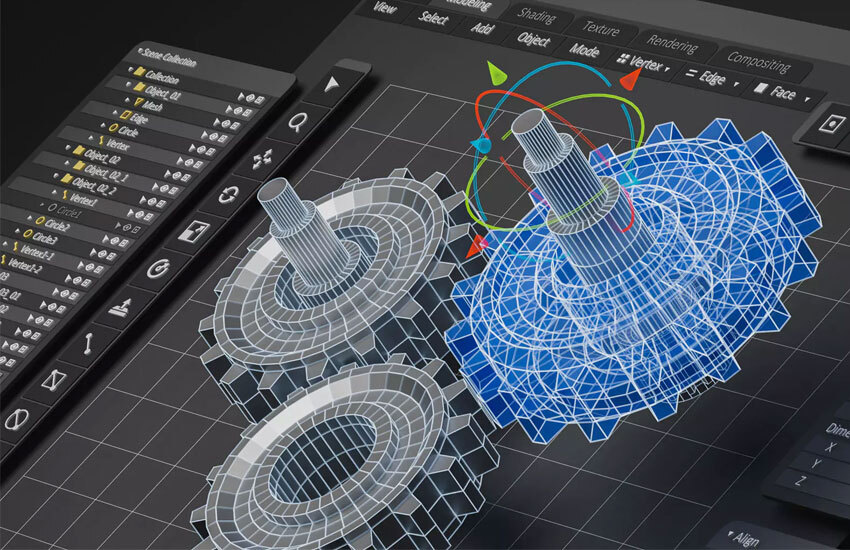

Teams may work together easily by utilizing sophisticated CAD tools for engineers, which allow each team member to view and operate on the same digital model. By enhancing communication and guaranteeing that mistakes are promptly identified and fixed, this shared experience helps to prevent problems throughout production.

Designers can conduct thorough tests and simulations using advanced CAD modeling techniques without requiring physical prototypes. These simulations provide important information about material behavior, structural integrity, and possible manufacturing difficulties. Before committing to physical manufacturing, engineers may swiftly detect form, fit, and function issues by employing 3D visualization for product design.

Another strong tool that raises accuracy is the 2D to 3D conversion in CAD. In order to better visualize intricate shapes and ideas, product designs frequently start out as 2D sketches before being transformed into 3D models. This conversion guarantees that engineers can identify possible problems, like component interference or assembly difficulties, that might not have been apparent during the 2D phase.

Furthermore, 3D modeling software aids in the creation of accurate digital prototypes that replicates a product's performance in the actual world. These prototypes enable thorough testing of the functionality and performance of the design, guaranteeing that the final product will function as planned.

Physical prototypes were frequently needed in conventional product development to assess a design's feasibility. But this approach is expensive as well as time-consuming. Designers can mimic the behavior of their goods in the real world without making physical models by employing digital prototyping using CAD.

For sectors like automotive and aerospace that depend on precision engineering, this digital transformation has changed everything. Highly comprehensive simulations of a product's performance under various situations, including pressure, stress, and temperature variations, are possible because of computer-aided design for precision engineering. Businesses can avoid costly physical prototypes and save time and money by spotting possible problems in the prototype early on.

In addition, CAD automation for faster development expedites the prototyping stage. Engineers can concentrate on more difficult jobs by using automated technologies to handle repetitive chores like making parts, updating models, and producing documentation.

Successful product development depends on efficient teamwork, and 3D product design solutions have elevated teamwork to a new level by allowing engineers, designers, and stakeholders to work together seamlessly, regardless of location. Using 3D CAD software teams can access and modify models in real time, whether it's adding components, changing dimensions, or simulating performance. This greatly lowers the risk of errors caused by misunderstandings or outdated versions of the design. Additionally, the use of AI-driven solutions within 3D modeling further improves collaboration, as tools like BricsCAD for 3D modeling provide AI-powered features like predictive analytics and real-time error detection. Potential conflicts or design faults are automatically flagged by these features, enabling teams to address them before they become expensive issues.

One of the greatest resources for engineers and designers is BricsCAD for 3D modeling when it comes to 3D modeling software. A great option for many different industries, BricsCAD is well-known for its user-friendly interface, with support for 2D and 3D design both and robust capabilities.

BricsCAD provides more flexibility and faster processing than typical CAD software. It facilitates collaboration with other teams and stakeholders by supporting a variety of file formats and integrating effectively with other software applications. When it comes to efficiency and error reduction, BricsCAD vs. standard CAD software clearly outperforms.

Whether you're working on architecture, industrial design, or CAD for mechanical design, BricsCAD offers the resources you need to produce precise, excellent 3D models fast. This guarantees that the finished product satisfies all specifications and lowers the possibility of mistakes occurring during the design phase.

Get to know more about the 3D modeling features in BricsCAD by diving into our blog post, “Exploring the Power of 3D Modeling in BricsCAD”!

3D modeling software is getting progressively more sophisticated as industries continue to change. As AI in business and AI-driven tools are integrated into CAD software, product creation is becoming more precise, efficient, and faster. These developments in advanced CAD modeling techniques and 3D design tools for engineering will keep transforming how products are designed and brought to market.

More automation, more AI capabilities, and more intricate simulations that provide a better knowledge of how goods will function in real-world settings are all part of the future of product development with CAD. Data analysis and predictive analytics will allow designers to foresee problems before they occur, guaranteeing that products are created with the least amount of risk.

To sum up, 3D modeling software is essential for lowering mistakes and enhancing the entire product development process. CAD software for product design increases accuracy, shortens time to market, and fosters better teamwork by enabling engineers to see, model, and test designs in a digital setting.

These cutting-edge tools, which range from 3D CAD modeling to digital prototyping with CAD, help companies create high-quality goods with fewer errors and less waste. The advantages are obvious, regardless of whether you are utilizing BricsCAD for 3D modeling or other 3D design solutions: more accuracy, quicker development, and better return on investment. The importance of 3D modeling in product creation will only increase with the advancement of technology, guaranteeing a more effective and error-free design process.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.