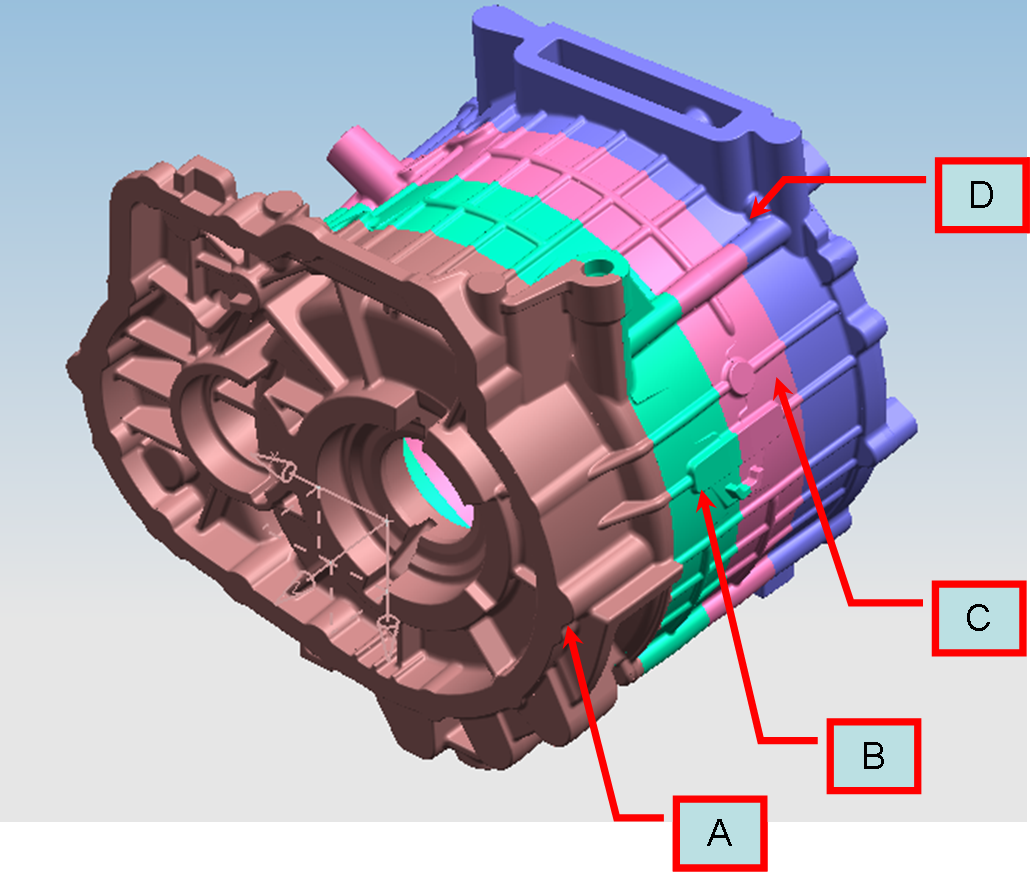

Our Automotive practice supports our engineering clients on their virtual product & process engineering activities for the development program of a vehicle in various stages from benchmarking, concept evaluation & validation, design development & optimization using components, sub-systems & full vehicle virtual prototypes.

We have worked with various engineering departments of reputable clients supporting them on activities such as:

We are proud to be the engineering partners to various International OEMs and Tier-1 suppliers for their niche design analysis. We have collaborated on various projects such as full vehicle assembly for new vehicle launch program while also providing the client's core design team with several valuable pointers toward structure-weight optimization strategies which is usually performed in the later stages of the vehicle design cycle.

Modelcam Technologies Pvt. Ltd. has set-up world class infrastructure including high performance computational nodes, workstations, utilizing software tools to cater to the customer requirements in the automotive segment.

Our offerings in CAD include:

*All projects executed at Customer end; Due to Non Disclosure Agreement the one's shown are with consent. Images are subject to copyright.

Design Process Automation / Engineering Configurations / CAD Customization / CAD Interfaces Design Automation / Knowledge Based Engineering (KBE) application development.

Design Automation applications are developed as add-ons over CAD platforms. Repetitive tasks that require rule-based decision making are ideal candidates for automation. These applications intelligently extract data, apply rules, make decisions and perform operations automatically. The knowledge base of product design comprises of elements like rules, tables, equations, etc. which are captured to create templates of new and variant designs. Design automation knits product design closely with manufacturing, support, finance, procurement & sales functions.

Based on our client needs & requirements, we support them in:

*All projects executed at Customer end; Due to Non Disclosure Agreement the one's shown are with consent. Images are subject to copyright.

To grow market share in today’s competitive automotive industry, companies need to bring innovative new products to market while reducing product development cycles and costs. Market leaders are focusing on ways to further differentiate their brands, exceed quality requirements and drive process efficiencies that will improve profit margins.

Pressure to stay ahead of innovative new designs being introduced by competitors while maintaining superior quality >

Shifting design responsibility to suppliers increases the level of complexity in the exchange of product design information, creating more room for error

Reducing product development lead times increases pressure on design, materials, procurement, and manufacturing to quickly incorporate complex customer changes

Identify opportunities to reduce design errors, integration, and testing times for vehicles by incorporating simulation design practices

Capture and reuse components, processes and past knowledge to accelerate time to market

Extend PLM system access to design partners, suppliers, dealers, and service providers around the globe

Improve product quality by applying consistent design and manufacturing processes

Manage historical supplier cost and performance data to make cost-effective sourcing decisions while reducing risk.

Optimize global manufacturing operations and capacity

Implement concurrent engineering processes to accelerate design cycles

Synchronize product planning and communication across all design and manufacturing partners by creating a single product record

Implement advanced quality management programs such as APQP and PPAP using PLM technologies to ensure consistency of design and manufacturing processes

Bridge gaps in the design processes and product manufacturability by integrating PLM system data and processes with other enterprise systems

Establishing "design-in-context" processes to integrate CAD data from disparate CAD applications, facilitating better design integrations and collaboration within the extended value chain.

*All projects executed at Customer end; Due to Non Disclosure Agreement the one's shown are with consent. Images are subject to copyright.

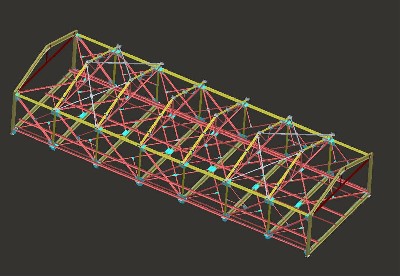

Modelcam Technologies Pvt. Ltd. is the leader in mobile equipment solutions. Our experienced team has the talent to design, select components, integrate an equipment design and prepare manufacturing designs of mobile equipment for various clients.

Modelcam Technologies Pvt. Ltd. offers mechanical engineering design solutions to customers that enable them to reduce turnaround time from design to manufacturing. Processes with clear metrics are drawn to meet customer’s expectations in terms of cost, delivery and quality

Modelcam Technologies Pvt. Ltd. CAD Service offerings range from conceptual to manufacturing designs for industry segments such as:-

Well defined Value chain systems of Modelcam Technologies Pvt. Ltd. employ value activities that would enable in:

*All projects executed at Customer end; Due to Non Disclosure Agreement the one's shown are with consent. Images are subject to copyright.

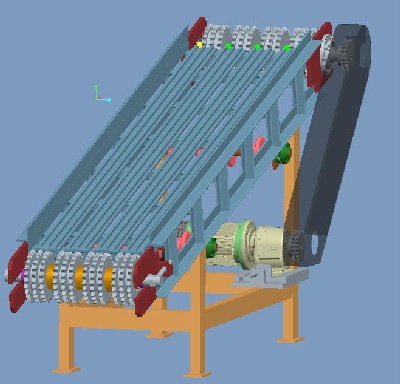

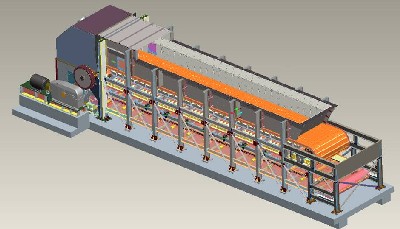

Owing to the backing of dedicated team and infrastructure, we are capable of executing design and engineering jobs of material handling and process plant equipment with efficiency. We are instrumental in offering services pertaining to Design & Engineering, Procurement & Outsourcing, Project Management, System Design, and individual equipments design such as Bucket Elevator, Screw Conveyor, Chain Conveyor, AEM and special purpose machines. We design, Prepare layout and elevations with construction drawings for process systems consisting of process machinery and material handling equipments.

Our system selection services include:

Our design and engineering jobs of material handling and process plant and equipment are widely used in the following:

Our design and engineering jobs of material handling and process plant and equipment are carried out in our modern infrastructure unit. Our infrastructure is setup over a vast area of 1200 square feet and is equipped with technology based machines that help us in executing the lay outing and designing processes in a streamlined manner. For fabricating the plants and equipment as per the requirements of our clients, we have installed the following machines at our unit:

*All projects executed at Customer end; Due to Non Disclosure Agreement the one's shown are with consent. Images are subject to copyright.

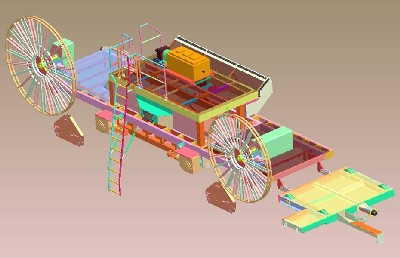

Modelcam Technologies Pvt. Ltd. offers a range of Industrial Special Purpose Machinery and products that are designed and developed in-house or are manufactured in partnership with top approved vendors nearby Pune and Chakan.

Capacity for continuous innovative design coupled with keen perception of customer needs which is required to maximize production efficiency and simultaneously reducing operating cost.

A wide range of material handling, packaging, transporting machineries with new ideas of design developed.

The support of High-end CAD products for designing special purpose machines where we optimize mainly the structural designs and with the additional support to reduce initial investment cost.

Design Engineering

*All projects executed at Customer end; Due to Non Disclosure Agreement the one's shown are with consent. Images are subject to copyright.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.