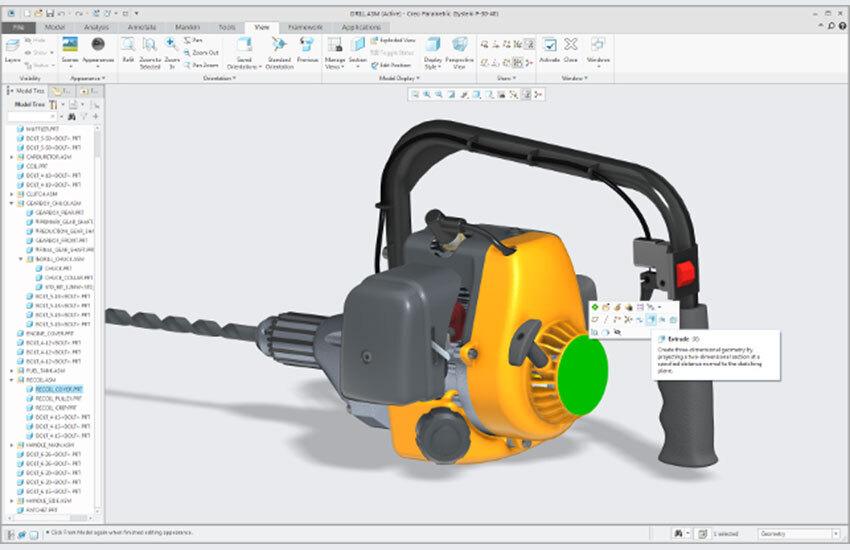

Creo, a powerful 3D CAD software from PTC, empowers engineers and designers to bring their innovative concepts to life. For experienced Creo users, mastering advanced techniques can significantly enhance your workflow, optimize designs, and elevate your overall productivity.

For experienced users, Creo software represents a powerful suite of tools that can elevate the design and engineering processes to new heights. Developed by PTC, Creo offers an extensive range of features designed to enhance productivity and innovation. As a PTC reseller, Modelcam Technologies understands the intricacies of Creo and provides valuable insights into advanced techniques that can help users maximize the potential of this CAD software.

In this blog, we'll explore advanced techniques in Creo 10, focusing on how experienced users can leverage these tools to optimize their design workflows, improve efficiency, and achieve superior results.

Learn more about new features and enhancements in Creo 10 through our blog, Exploring Creo 10: New Features and Enhancements!

For complex projects, managing assemblies in Creo can be challenging. Here are some advanced techniques to streamline your assembly process:

Component Patterning: Utilize the pattern feature to replicate components efficiently. Advanced patterning options allow you to create complex patterns and mirror assemblies with precision. This can be particularly useful for components that need to be repeated in various configurations.

Assembly Constraints: Use advanced constraints to control the movement and placement of components within an assembly. Creo's powerful constraint management tools enable you to define and adjust constraints easily, ensuring that parts fit together accurately and function as intended.

Top-Down Design: Implement top-down design strategies by creating assembly-level features and parameters. This approach allows you to design components based on the overall assembly requirements, improving coherence and reducing errors.

Parametric modeling is a core strength of Creo, and mastering advanced techniques can significantly enhance your modeling capabilities:

Driven Dimensions and Relations: Use driven dimensions and relations to control and update model features dynamically. By linking dimensions and parameters, you can create models that adjust automatically when changes are made, improving design flexibility and reducing manual adjustments.

Family Tables: Leverage family tables to manage variations of a part or assembly efficiently. This technique allows you to create multiple instances of a component with different dimensions, materials, or configurations without having to model each instance separately.

Advanced Sketching: Utilize advanced sketching tools to create complex shapes and profiles. Creo offers a range of sketching options, including splines, arcs, and other geometric entities, enabling you to design intricate features with precision.

Creo's advanced surfacing capabilities go beyond basic extrusions and revolves. Experienced users can create intricate, organic shapes using tools like blends, sweeps, and lofts. These techniques are perfect for designing aerodynamic components, fluid housings, and other applications requiring complex geometries.

Here are some advanced surfacing techniques to explore:

Blends: Create smooth transitions between surfaces by defining multiple profiles and controlling the tangency between them.

Sweeps: Generate complex shapes by sweeping a profile along a defined path, allowing for the creation of curved ducts and pipes.

Lofts: Create smooth surfaces by transitioning between multiple profiles, ideal for designing organic shapes like turbine blades or car bodies.

Modelcam Technologies, a Cad software reseller, can provide valuable resources and training programs to help you master these advanced surfacing techniques. Their team can guide you through complex surfacing workflows and demonstrate how to achieve optimal results for your specific design needs.

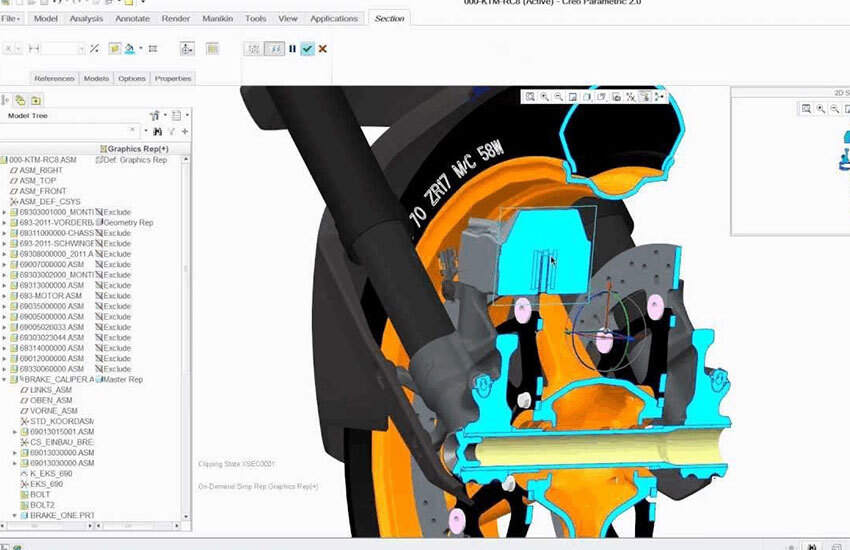

Design validation is critical for ensuring that your models perform as expected. Advanced techniques in Creo can help you validate your designs more effectively:

Simulation and Analysis: Utilize Creo’s built-in simulation and analysis tools to test your designs under various conditions. Perform structural, thermal, and motion analysis to identify potential weaknesses and optimize your designs for performance and durability.

Design for Manufacture (DFM): Implement DFM techniques to evaluate your designs from a manufacturing perspective. Creo offers tools to check for manufacturability issues, such as draft angles, undercuts, and assembly constraints, ensuring that your designs are practical and cost-effective to produce.

Tolerance Analysis: Use tolerance analysis tools to assess how dimensional variations affect your design’s performance. Creo’s tolerance analysis features help you optimize tolerances and ensure that your parts fit together correctly during assembly.

Automation can significantly enhance productivity and consistency in your design workflows. Here’s how to leverage automation in PTC Creo:

Pro/TOOLKIT and J-Link: Utilize Pro/TOOLKIT and J-Link for custom automation and integration. These tools allow you to create custom applications and scripts that automate repetitive tasks, streamline workflows, and integrate Creo with other software systems.

Design Automation: Implement design automation techniques to create parametric models that update automatically based on predefined rules. This can be particularly useful for generating variants of a design or managing large-scale projects with complex requirements.

Template Management: Create and use templates for standard parts, assemblies, and drawings to reduce modeling time and ensure consistency across projects. Creo allows you to define templates with predefined features, dimensions, and annotations, streamlining your design process.

You can go through our interesting blog, Optimizing Design Workflows with Creo 10 for more information on How to Optimize Design Workflows with Creo 10 with some tips and tricks.

Effective collaboration is essential for successful design projects. Creo offers several features to enhance collaboration and communication:

Data Management: Use PTC Creo’s data management tools to organize and manage your design data efficiently. Integration with PTC’s Windchill PLM system allows for seamless data sharing, version control, and collaboration across teams.

Annotation and Markup: Leverage Creo’s annotation and markup features to communicate design changes and feedback effectively. Use annotations to highlight specific areas of interest and provide detailed comments for review.

Integrated Collaboration Tools: Take advantage of integrated collaboration tools, such as Creo View and ModelCHECK, to facilitate real-time collaboration and ensure design quality. These tools enable teams to review and validate designs collaboratively, improving decision-making and reducing errors.

Leveraging advanced techniques in PTC Creo software can significantly enhance your design capabilities and streamline your engineering workflows. By mastering advanced assemblies, parametric modeling, surfacing techniques, design validation, automation, and collaboration features, experienced users can unlock the full potential of Creo and achieve superior design outcomes.

As a leading PTC reseller, Modelcam Technologies provides expert support and resources to help you make the most of Creo software. Whether you’re exploring Creo 10 or seeking guidance on advanced techniques, Modelcam Technologies is here to assist you in optimizing your CAD software experience.

Explore the advanced features of Creo and elevate your design processes today. For more information and expert assistance, visit Modelcam Technologies and discover how we can help you achieve excellence in your engineering projects with Creo.

Let’s connect: www.modelcamtechnologies.com

Email: sales@modelcamtechnologies.com

Mobile no : +91 8237016167

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.