Artificial Intelligence (AI) is revolutionizing the manufacturing industry, bringing about major transformations in how production processes are managed and optimized. With advancements in AI-powered technologies, manufacturers are now able to improve efficiency, reduce costs, and enhance product quality. As part of Industry 4.0, AI has become a driving force for smart factories, reshaping how products are designed, produced, and delivered.

AI in manufacturing involves incorporating artificial intelligence technologies to automate, optimize, and improve different stages of the production process. AI systems use data, machine learning algorithms, and advanced computing to analyze, predict, and make decisions autonomously or with minimal human intervention. By incorporating AI, manufacturers can achieve unprecedented levels of efficiency, accuracy, and flexibility across their operations. AI-powered manufacturing systems use techniques like predictive maintenance, robotics process automation (RPA), and process optimization to streamline production workflows and improve overall performance.

AI in manufacturing integrates data collection, machine learning, and automation to optimize processes. Real-time sensor data helps monitor equipment and inventory, while AI-driven machine learning detects patterns, predicts outcomes, and enhances decision-making. Robotics automate tasks for precision and efficiency, while computer vision ensures quality control. Predictive analytics prevents downtime, and NLP enables seamless human-machine interaction, boosting productivity and cost savings.

Here's how AI in manufacturing operates in practice:

Data Collection: The real-time data collected from sensors, machines, and other connected devices is used to monitor various processes, from equipment performance to inventory levels.

Machine Learning: Using machine learning algorithms, AI models analyze the collected data to detect patterns, predict outcomes, and make informed decisions. These algorithms are trained on vast datasets to continuously improve their predictions and decision-making over time.

Automation: AI enables the automation of repetitive tasks, from assembly to packaging, using robots and robotics process automation (RPA). This allows for faster, more accurate production with reduced human error.

Computer Vision: AI systems analyze visual data from cameras and sensors to identify defects, measure dimensions, and monitor production processes.

Predictive Analytics: AI systems employ quantitative analysis and predictive algorithms to forecast potential issues, such as machinery breakdowns or supply chain disruptions. This proactive approach to maintenance, known as predictive maintenance, helps manufacturers avoid costly downtime and extends the lifespan of their assets.

Natural Language Processing (NLP): AI-powered systems can understand and respond to human language, enabling communication with machines and systems.

AI offers numerous benefits for manufacturers, including:

Enhanced Efficiency: AI-driven solutions optimize production processes, reducing waste and improving throughput. AI for manufacturing process optimization helps companies streamline workflows and ensure that resources are used effectively. AI-powered automation can streamline processes, reduce labor costs, and increase production output.

Cost Savings: By automating tasks and predicting maintenance needs, AI reduces operational costs and minimizes downtime. Manufacturers can also cut back on labor costs and reduce the risk of expensive machinery breakdowns.

Improved Quality: AI-powered quality control automation ensures that every product meets the highest standards. AI systems can detect defects and inconsistencies in real time, improving product quality and reducing the need for costly rework. AI-driven quality control systems can detect defects and inconsistencies with greater accuracy, leading to higher-quality products.

Predictive Maintenance: By predicting equipment malfunctions, AI allows for scheduled maintenance, reducing unexpected downtime.

Real-Time Decision-Making: AI systems enable manufacturers to make data-driven decisions in real time, allowing for faster responses to changes in demand, production issues, or market conditions.

Optimized Supply Chain: AI can optimize inventory levels, improve logistics, and forecast demand, leading to a more efficient supply chain.

Increased Flexibility: With AI, manufacturing systems become more adaptable to changing production requirements. Smart manufacturing with AI allows for the quick reconfiguration of production lines to handle different product types, sizes, or volumes.

AI has a wide range of applications in manufacturing, each contributing to the improvement of production processes and operations:

AI-Powered Process Optimization: AI optimizes every step of the production cycle, from procurement to delivery. By analyzing production data, AI algorithms identify inefficiencies, reducing cycle times and improving overall productivity.

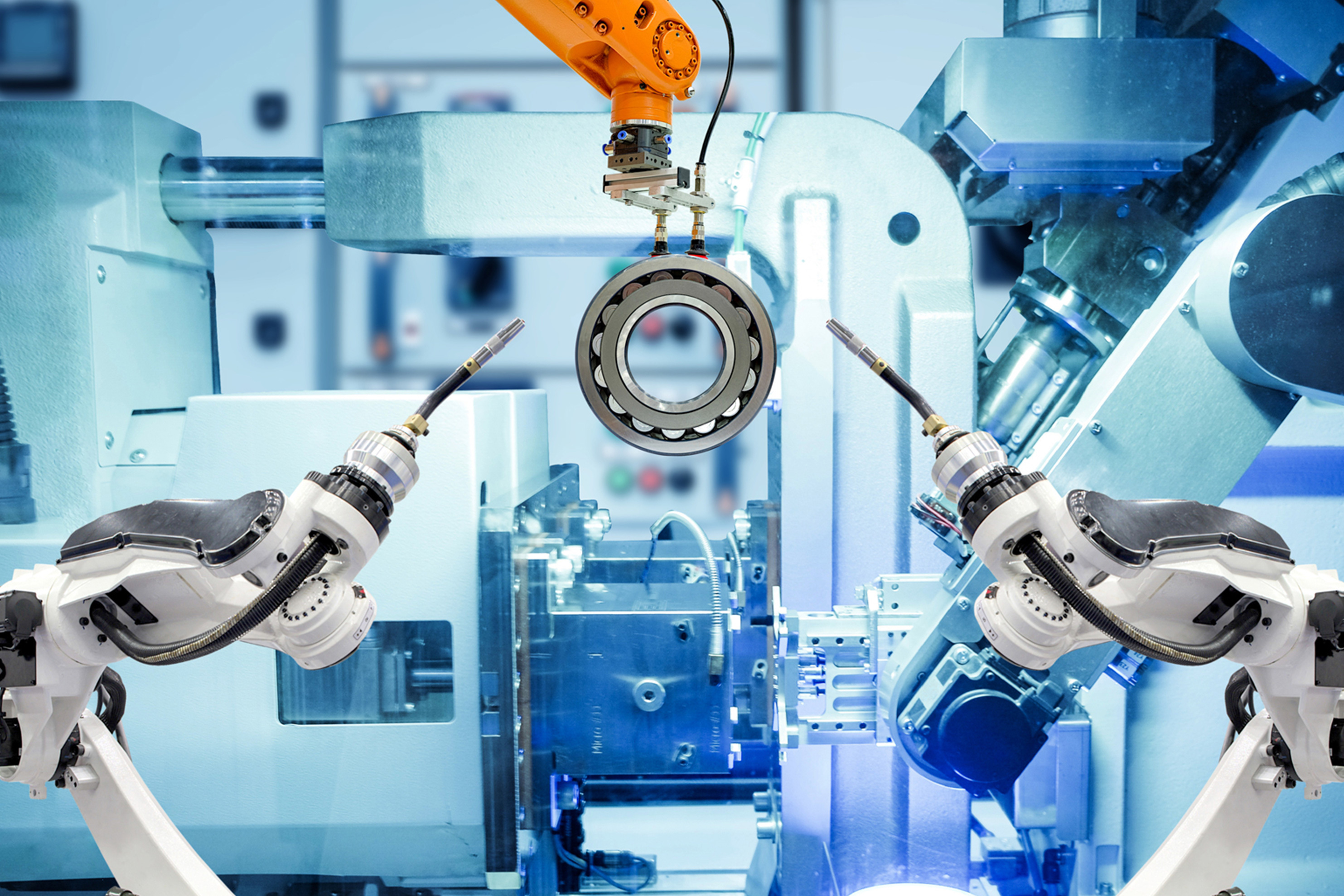

Robotics and AI Integration: Robots powered by AI can handle repetitive, high-volume tasks with greater precision and flexibility than traditional automation. AI-driven robots adapt to changes in their environment and can perform a variety of tasks, such as assembly, packaging, and material handling.

AI Chatbots for Industry: AI-driven chatbots are transforming customer service in manufacturing. By automating customer support, these AI chatbots for industry provide instant responses to customer queries and can handle complaints, freeing up human resources for more complex tasks.

Predictive Maintenance: AI uses historical data and real-time machine monitoring to predict equipment failures before they occur. This approach minimizes unexpected downtimes and allows manufacturers to perform maintenance only when necessary, leading to cost savings.

Supply Chain Optimization with AI: AI improves supply chain management by predicting demand, optimizing inventory levels, and identifying the most efficient shipping routes.

Quality Control Automation: AI uses computer vision and machine learning to inspect products during the production process. This automated system detects defects, ensuring only high-quality products are delivered to customers.

AI in Factory Automation: With AI in industrial automation, factories become more autonomous, with machines and systems capable of making decisions based on real-time data. This reduces the need for human intervention, increasing speed and efficiency.

Smart Manufacturing Solutions: Smart factories, powered by AI, integrate various technologies such as the Internet of Things (IoT), machine learning, and robotics. These systems enable manufacturers to monitor, control, and optimize production in real-time.

Machine Learning in Manufacturing: Machine learning algorithms can analyze large datasets to identify patterns, make predictions, and optimize processes.

A digital twin is a computerized model of a genuine asset, procedure, or system that uses real-time data to replicate actual conditions. Digital twin technology, when paired with artificial intelligence, improves manufacturing by facilitating the analysis, simulation, and optimization of processes prior to implementing changes in the real world.

How AI-Powered Manufacturing Uses Digital Twins:

Real-Time Data Integration: To build a digital model, sensors gather real-time data from machinery, equipment, and manufacturing lines.

AI-Driven Analysis: To forecast performance, spot inefficiencies, and recommend enhancements, AI algorithms examine the data from the Digital Twin.

Predictive simulation: Predictive simulation lowers risks and expenses by allowing manufacturers to digitally test various production scenarios prior to making changes.

Continuous Optimization: To make better decisions and increase operational effectiveness, the Digital Twin gains knowledge from analytics driven by AI.

Digital twin technology and artificial intelligence (AI) in manufacturing are revolutionizing production by facilitating process optimization, predictive maintenance, and real-time monitoring. By building virtual versions of real assets, digital twins enable AI-driven research to find inefficiencies and improve decision-making. This collaboration guarantees better product quality, lowers downtime, and increases operational efficiency. Digital twins will be essential to the development of smarter, more flexible production systems as AI advances.

©Copyright 2025. All rights reserved by Modelcam Technologies Private Limited PUNE.